- Products / Technology

- Technology

- SDGs /CSR /Environment

- NEWDec. 09, 2024

Commence Full-Fledged Operation of the Biogas Experimental Plant for the Ryuo Town Biomass Industrial City Concept - To facilitate Ryuo Town’s resource circulation project through a collaboration by crop farmers, livestock farmers, and manufacturers -

Dec. 09, 2024

Ryuo Town

DAIHATSU MOTOR CO., LTD.

Ryuo Town in Shiga Prefecture has been promoting the Ryuo Town Biomass Industrial City Concept to realize a sustainable local community by utilizing and recycling local biomass resources through a collaboration among crop farmers, livestock farmers, and manufacturers. As part of this initiative, a “biogas experimental plant,” which was constructed by Daihatsu Motor Co., Ltd. (hereinafter “Daihatsu”) based on the vehicle manufacturing approach, has commenced full-fledged operation in the Daihatsu Shiga (Ryuo) Plant 1st District. This biomass industrial city concept, with active industry involvement, is progressive.

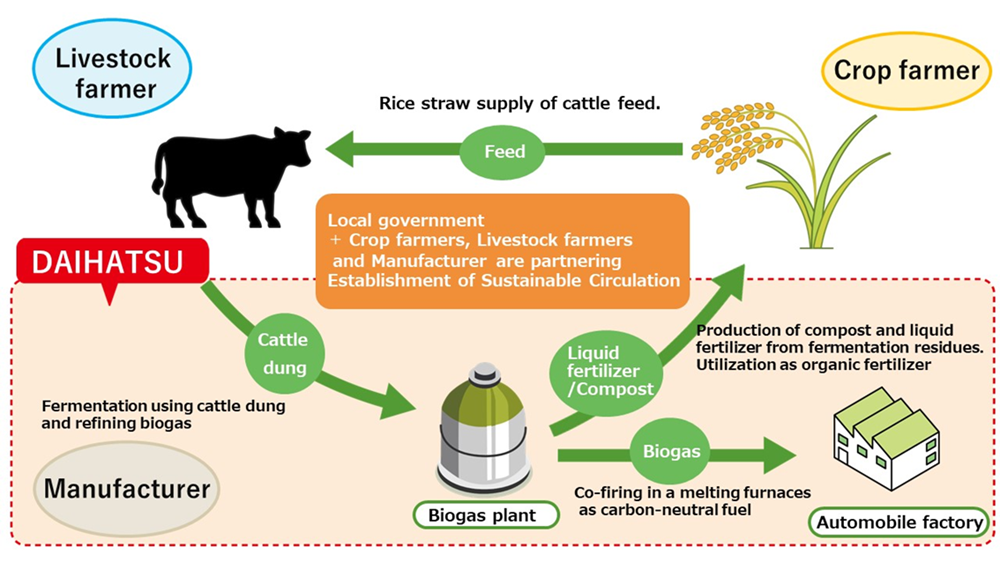

The Biomass lndustrial City Concept aims to develop environment-friendly and disaster-resistant villages and towns centered around the biomass industry by establishing an integrated system from raw material collection and transportation to production and consumption of biogas while ensuring their economic efficiency. The biomass industrial cities are selected by seven related ministries*. Ryuo Town was certified as a biomass industrial city in January 2023 ahead of other municipalities in Shiga Prefecture and began promoting the plan. As part of the initiative, the Biogas Project, led by Ryuo Town, aims to attain biomass resource circulation within the town by bringing together crop farming, livestock farming (Omi Beef), and manufacturing (vehicles) businesses. The project involves using cattle dung to produce biogas (methane gas) for consumption as a carbon neutral fuel and using fermentation residues to produce compost and liquid fertilizer for use as organic fertilizer.

Having been subsidized by the New Energy and Industrial Technology Development Organization (NEDO) since 2021, Daihatsu has been engaging in basic research on the use of Omi cattle dung as a fermentation material, biogas production technology development, and launch of a unique biogas experimental plant based on the vehicle manufacturing approach.

Daihatsu is striving to launch a larger-scale commercial plant in the future, aiming to produce biogas from approximately 20 tons of cattle dung per day, equivalent to approximately 10% of the amount of gas required for aluminum melting at a foundry, to contribute to achieving carbon neutrality at automobile plants.

Through these projects, Daihatsu and Ryuo Town will continue to pursue brand value enhancements for environment-friendly products made in Ryuo Town (agricultural products such as Omi Beef and Omi Rice as well as vehicles), promote local revitalization, and aim to become a sustainable local community

* Cabinet Office; Ministry of Internal Affairs and Communications; Ministry of Education, Culture, Sports, Science and Technology; Ministry of Agriculture, Forestry and Fisheries; Ministry of Economy, Trade and Industry; Ministry of Land, Infrastructure, Transport and Tourism; and Ministry of the Environment

Outline of the Biogas Project

-Resource Circulation Through a Collaboration by Agriculture and Industry

- Treat and ferment Omi cattle dung in the plant to produce biogas and use as a carbon-neutral fuel

- Fermentation residues are converted into compost and liquid fertilizers, which are used in organic farming to contribute to the realization of sustainable agriculture.

- Stably supply rice straw as cattle feed

(Reference)

- Ryuo Town Biomass Industrial City Concept https://www.town.ryuoh.shiga.jp/biomass/top/top.html

Outline of the Biogas Experimental Plant

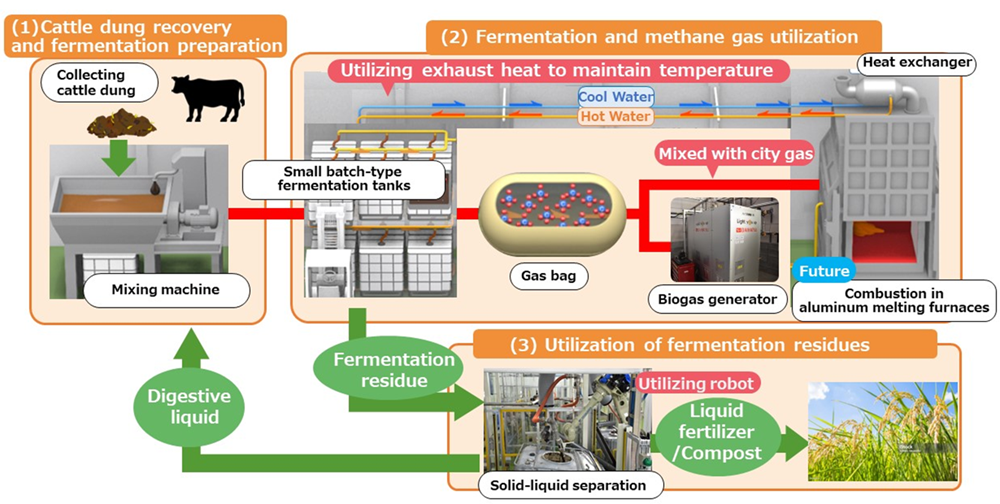

1. Overview of the experimental plant

- Unique dry methane fermentation technology was developed considering the properties of cattle dung with low moisture content.

- The fermentation tank moves as the production process progresses, similar to the vehicle manufacturing process.

- The plant's equipment was developed by us. The equipment was manufactured in-house, by a nearby partner manufacturer, or modified from an existing facility.

- Exhaust heat from the aluminum melting furnace in the plant is used to keep methane fermentation temperatures (for CO2 emissions reduction).

- A vehicle designer engaged in the plant color design.

2. Process of the experimental plant

(1) Cattle dung collection and fermentation preparation

- Collect approximately 2 tons of cattle dung per day from farms

- Mix cattle dung, liquid containing methanogens (digestive liquid), and water and put them in the fermentation tank

(2) Fermentation and methane gas utilization

- Ferment the materials in the fermentation shelf installed that is accommodable approximately 80 small batch-type fermentation tanks and control fermentation progress in each tank

- Use biogas-fueled generators developed by utilizing small vehicle engines to generate carbon-neutral electricity for automobile plants

(3) Utilization of fermentation residues

- Separate fermentation residues into solid and liquid to produce compost and liquid fertilizers

- Use them as organic fertilizers in farms in Ryuo Town to contribute to the branding of foodstuffs produced by environment-friendly agriculture

- Use some liquid fertilizers containing rich methanogenic bacteria (digestive liquid) as seeds for the next fermentation

(Reference)

- Sustainability initiative on Daihatsu Official Website https://www.daihatsu.com/csr/environment/lcs/manufacture.html

- Presentation material (URL) https://www.daihatsu.com/news/2024/20241209-4_guidance.pdf

*

This press announcement is based on results obtained from JPNP10020, a project subsidized by the New energy and Industrial Technology Development Organization (NEDO).