- Notification

- Products / Technology

- Technology

- NEWMar. 13, 2023

Daihatsu Receives the 55th Ichimura Industrial Prize in Industry for Distinguished Achievement in Developing the Continuously Variable Transmission for Rear-Wheel Drive and Four-Wheel Drive Mini Commercial Vehicles ~Improving the Ride Quality and Fuel Efficiency of Mini Commercial Vehicles by Adopting CVT for Front Engine/Rear-Wheel Drive Vehicles~

Mar. 13, 2023

Daihatsu Motor Co., Ltd.

Daihatsu Motor Co., Ltd. (hereinafter “Daihatsu”) announced today that it has received the 55th Ichimura Prize in Industry for Distinguished Achievement from the Ichimura Foundation for New Technology, in recognition of the development of the continuously variable transmission (hereinafter “CVT”) for rear-wheel drive and four-wheel drive mini commercial vehicles. The CVT has been used in the mini commercial vehicles, the Hijet Cargo, the Hijet Truck, and the Atrai since December 2021.

The prize is awarded to those who have contributed to and made significant achievements in the development of industrial fields through the development of superior domestic technology, and this is the first time in 20 years that Daihatsu has received the prize since the 35th Ichimura Industrial Prize, which it was awarded for its research on the Intelligent Catalyst (self-regenerative catalyst for exhaust gas purification).

Awarded Theme

Development of Continuously Variable Transmission for Rear-Wheel Drive and Four-Wheel Drive Mini Commercial Vehicles

Prize Winners

Shinya Yonemoto, Kanya Hitomi, Osamu Arai

Development Background

Mini commercial vehicles have been cherished by customers as a “working partner” in a wide range of industries, from primary industries such as agriculture to the construction and delivery industries, in both rural and urban areas nationwide. By adopting a cab-over*1 and FR layout*2 ideal for mini commercial vehicles that are required to carry a large amount of cargo at once, Daihatsu has pursued load capacity by maximizing the luggage space and deck, driving performance that can be trusted even on rough roads, and durability.

In recent years, the diversification of users, such as women, seniors, and foreigners, as well as the need to prevent cargo shifting due to the increase in small-lot deliveries, have created a need for better drivability and a smoother ride than in the past. In addition, a significant improvement in fuel efficiency was also essential against the backdrop of environmental issues, so it was necessary to evolve from the existing 4-speed AT to CVT, which is the mainstream in mini passenger vehicles.

Technology Overview

To address the above issues, Daihatsu has developed a new CVT for front engine/rear-wheel drive vehicles, a first for mini commercial vehicles*3, as well as an electronically controlled 4WD system with three modes that can achieve driving performance suited to various road conditions and purposes. In particular, CVT for front-engine/rear-wheel drive vehicles must be compact and low-profile to fit into the limited space available for mounting the unit in the cab-over layout, and it must also have endurance reliability required for commercial vehicles. The following technologies have been developed to overcome these challenges.

*1: A layout in which the engine and transmission are placed under the passenger space (cabin) in order to secure luggage space and deck length.

*2: A layout of front engine/rea-wheel drive that maximizes driving force by driving the rear wheels under the luggage space and deck where heavy cargos are carried.

*3: As of December 2021, according to research conducted by Daihatsu. Other companies have vehicles that are using it for the first time at the same time.

Technologies

-

Output-speed reduction type CVT “Fuel Efficiency Technology”

Fuel efficiency has been improved by approximately 17%*4 by adopting CVT with a wide ratio range and optimizing the gear ratio of speed reduction.

-

Forward-backward parallel arrangement “Miniaturization Technology”

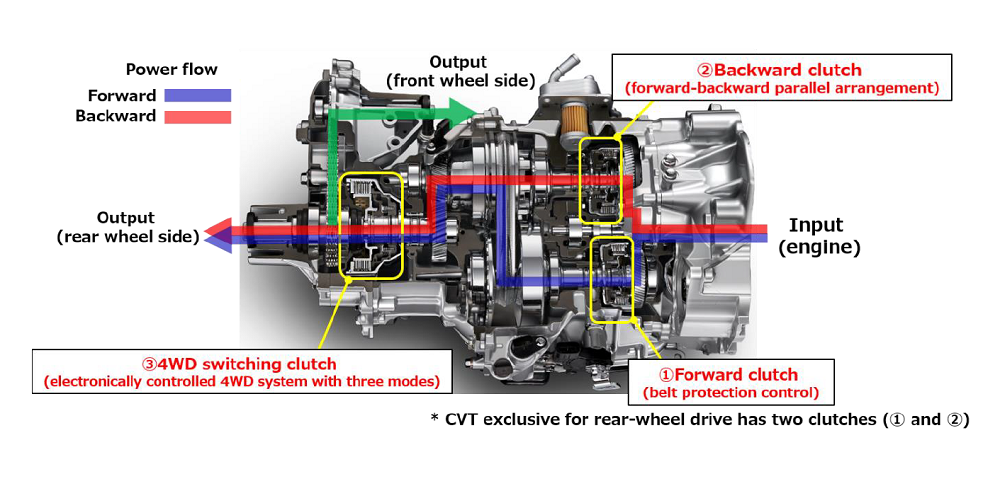

Forward/backward switching is configured with two shafts, one on each side of the input shaft, to lower the height and provide the luggage space equivalent to that of conventional AT models. (see Fig. 1)

-

Belt protection control “Endurance Reliability Technology”

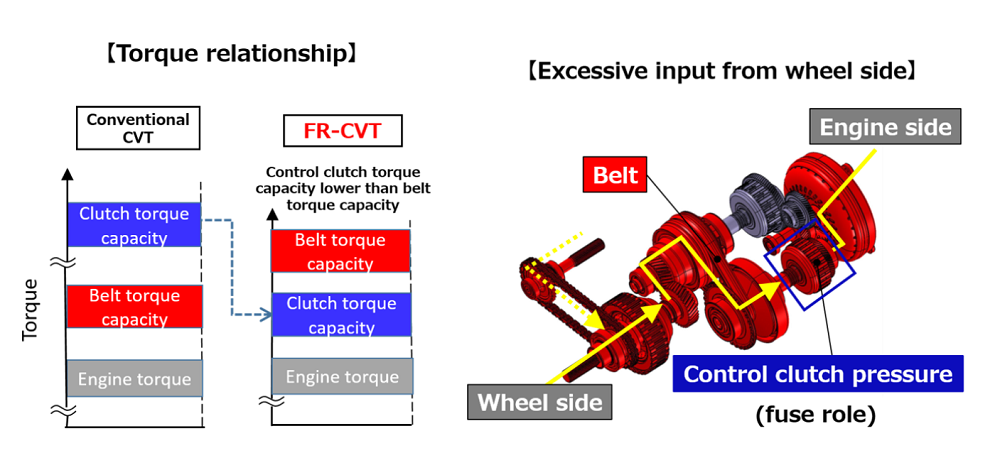

By controlling the clutch pressure all times, the clutch is allowed to slip and release in response to excessive input, thereby ensuring belt endurance reliability. (see Fig. 1 and Fig. 2)

-

Electronically controlled 4WD system with three modes “4WD Technology”

The electronically controlled 4WD system with three modes (2WD/4WD LOCK/4WD AUTO) has been developed with “4WD AUTO” that automatically controls torque distribution from FR (front-engine/rear-wheel drive) to 4WD (four-wheel drive) depending on road conditions to improve driving performance in diverse environments. (see Fig. 1)

Figure 1: Structure of FR-CVT

Figure 1: Structure of FR-CVT

Figure 2: Belt protection control

Figure 2: Belt protection control

Daihatsu will provide optimal mobility for each customer based on the group slogan “Light you up” and continue to pursue the realization of carbon neutrality by 2050 through further pursuit of fuel-efficient technologies.

*4: Compared with conventional automatic specifications in representative models, according to research conducted by Daihatsu.