Safety and Health

Basic Philosophy: Safety and Health of Employees Form the Foundation of Corporate Activities

The Daihatsu Group is committed to enriching the lives of our customers by working closely with them through the creation of a mobility society.

In addition, with the vision of becoming a company that is supported by customers, communities, and society, we are working to establish the following management policies: "Creating a workplace culture where employees grow together with smiles," "Conducting correct management with people at the center," and "Manufacturing and creating things that are trusted by society."

We are committed to creating a safe, secure and comfortable workplace by implementing and promoting this management policy.

We also support the health maintenance and promotion of all employees and their families.

Declaration of Safety and Health

Safety

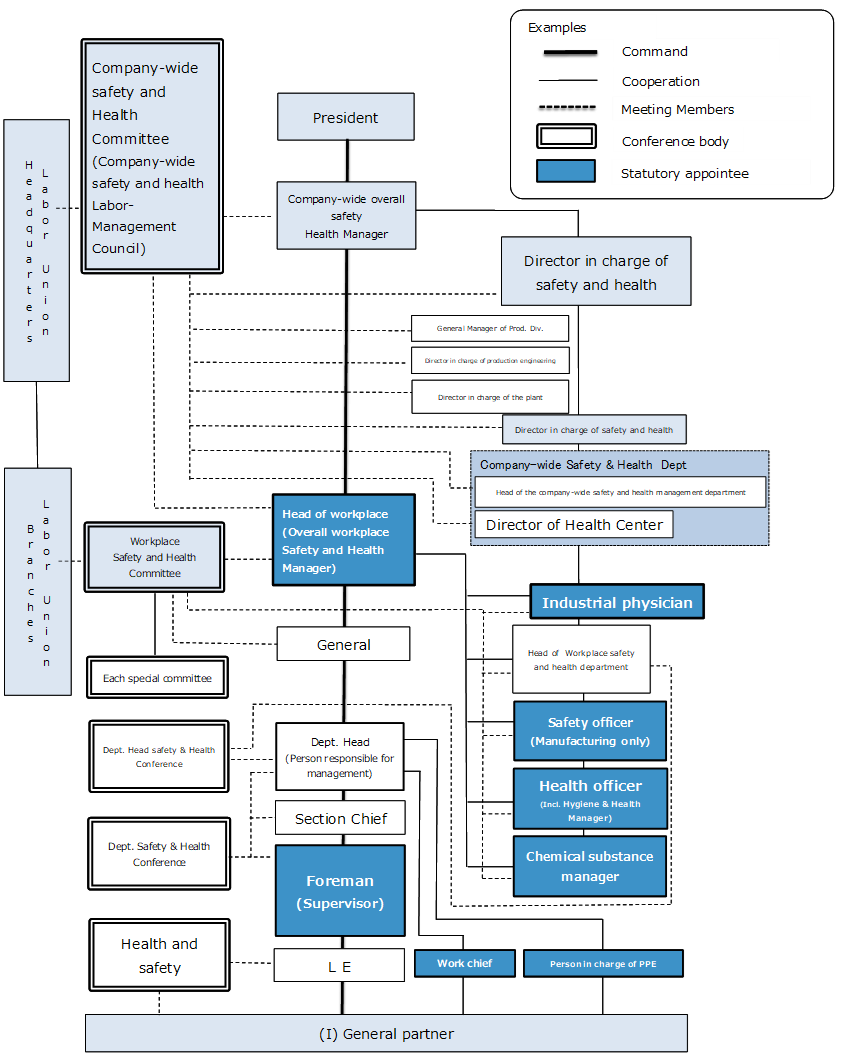

Daihatsu has established “Organization for Safety and Health Management” according to internal rules, and carries out proper safety management and administration based on managers of various ranks.

The company also promotes the establishment of an occupational safety and health management system, with the goal of continually improving the level of its safety and health management.

Under this management system, Daihatsu ensures it complies with national laws and regulations as well as internal rules; it seeks to improve work safety through regular internal audits and risk assessments of dangerous work.

Daihatsu’s risk assessments fall into two categories: assessments of new facilities and processes; and assessments of existing facilities and work methods. In both these categories, the company investigates danger and hazard, and seeks to reduce risks.

Organization for Safety and Health Management Chart

Safety and Health Committee

Safety and Health Committee

Safety and Health Committee

The Company-wide Safety and Health Committee

(Company-wide Safety and Health Labor-Management Council) are held meeting twice a year.

The purposed is to deliberates on company-wide issues related to safety and health, ensure the safety and health of employees, promote the creation of a safe and comfortable workplace, decides on action policies, and exchanges opinions between top management and labor.

In addition, the Safety and Health Committee are held monthly meetings at each business site to exchange opinions related to safety and health issues.

Safety and health education

Safety and health education

Safety and health education

Daihatsu has established internal rules regarding the safety and health education of new recruits, employees being promoted to managerial or supervisory positions, and employees engaged in work judged to be danger and hazard.

Daihatsu independently identifies some work processes as Malfunction Correction Requiring Special Permission, even if it is not defined as high-risk under the Industrial Safety and Health Act; for such work processes, the company has established a Designated Work System that only allows certified employees who have completed the relevant training to carry out such work.

Activities to eliminate risks and promote intrinsic safety

Daihatsu carries out activities that promote the three pillars of intrinsic safety*, primarily focused on its production sites, which are thought to be at high risk of accidents.

These activities comprise part of the company’s long-term safety and health initiatives, and their content is updated and expanded on an annual basis.

* Intrinsic safety measures seek to secure safety by eliminating risk at the source—such as materials and facilities risks—and by mitigating the potential harm caused by accidents.

Daihatsu carries out activities aimed at eliminating various abnormalities from its production lines.

To this end, it visualizes conditions leading to these abnormalities so that it can identify their fundamental causes, then implements measures that target the sources of the abnormalities themselves.

Daihatsu works to prevent accidents resulting from contact between its employees and work vehicles.

Forklifts are particularly prone to causing serious accidents. Consequently, the company is in the process of switching from forklift transportation to safer transportation methods, ensuring forklifts do not operate near areas in which people are working, and establishing walkway where people can walk safely.

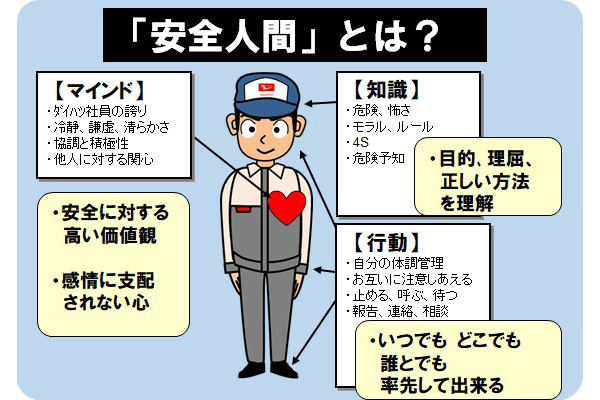

In order to develop human resources who abide by rules, all Daihatsu employees take part in Safety Dojos that have been established throughout the company; employees receive training at these dojos, then takes tests—they are certified “Safety Persons” if they pass the test.

After receiving Safety Person certification, employees continue to receive training every year to renew their certification.

In addition, Safety Dojos and company work sites are home to “Risk experience corners,” where employees can learn about various risks, such as getting caught in equipment, and receiving electric shocks.

Personnel reading safety rules out loud

Personnel reading safety rules out loud

(performed before work)

Training on proper use of a work trolley

Training on proper use of a work trolley

Securing the safety of employees at partner companies

Daihatsu not only works to prevent work accidents involving its own employees, it also seeks to prevent accidents involving the employees of partner companies. This includes workers constructing buildings or carrying out repairs on Daihatsu grounds, and workers conducting cleaning and maintenance on Daihatsu facilities.

Daihatsu has drawn up special safety regulations for construction work that takes place in its grounds, in which workers are particularly at risk of accidents liable to cause serious injuries, such as fires or falls from high places. In these cases, Daihatsu demands that partner companies incorporate safety measures based on risk assessments from the planning stage of any construction work.

In addition, Daihatsu organizes safety patrol teams comprising construction planning staff and partner company employees; these teams undertake inspection patrols, and work to prevent construction accidents.

Prevention of health damage by chemical substances

We conduct chemical substance risk assessments when we adopt or change a new chemical substance.

We are taking steps to minimize the exposure of employees and prevent health damage by implementing reduction measures such as substituting with less hazardous substances, installing ventilation equipment and other sanitary engineering measures, improving work procedures and other administrative measures, and considering the use of effective protective equipment.

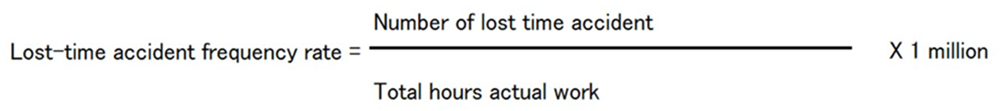

Occupational accidents, injuries and diseases

We are making efforts to eliminate occupational accidents and injuries.

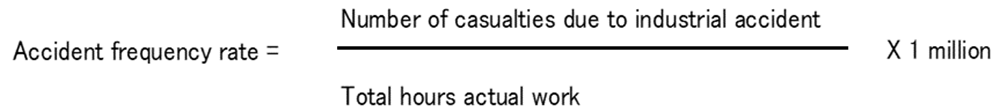

As results of 2024, we are recorded only 9 occupational accidents with zero deaths. Total accident frequency rate is 0.36% and lost-time accident frequency rate is 0.08% at domestic sites. At overseas sites, there were recorded 6 occupational accidents and zero deaths.

Creation of Comfortable Work Environment

Labor and management workplace environment patrol

Labor and management workplace environment patrol

We are working to create a comfortable working environment by taking measures such as improving hot and cold conditions at plants. Labor and management carry out workplace environment patrols twice a year. While listening to the voices of workers, we promote efficient measures against heat and cold that also take the environment into consideration and reduce CO2 emissions.

In addition, we focus on the prevention of heat stroke by taking measures against clothing such as air-conditioned clothes and setting the time to replenish water during the operation of the production line.

Health

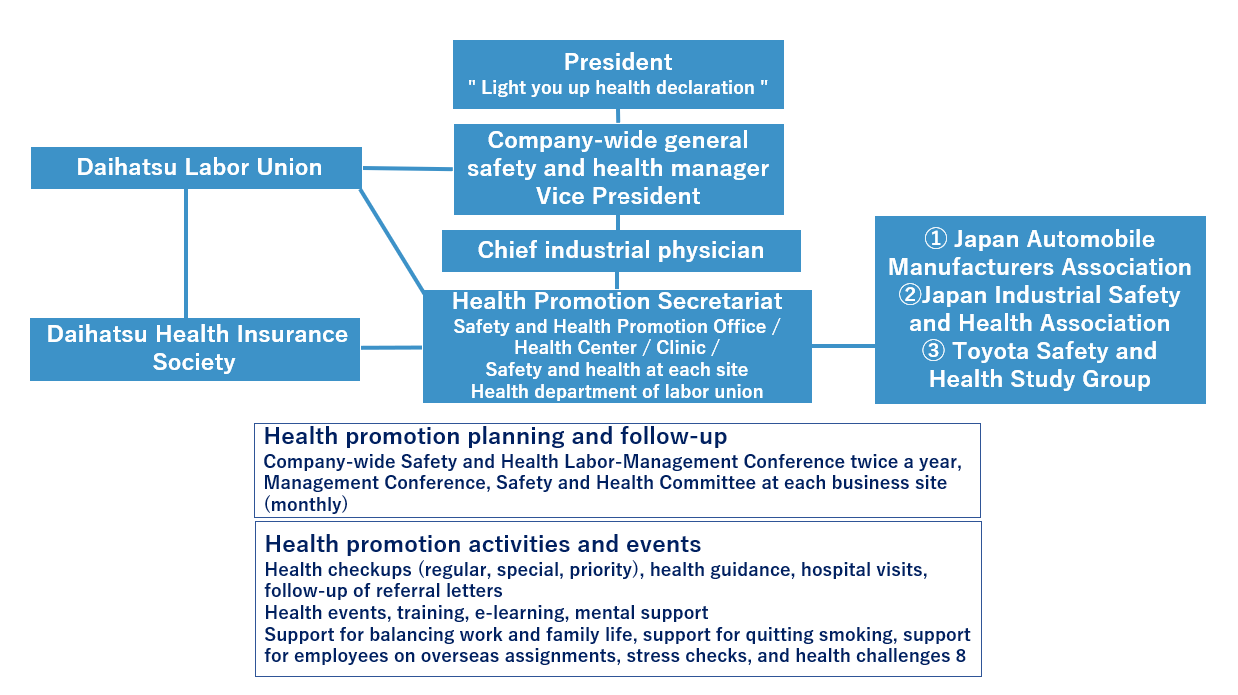

With the aim of mass production of happiness, Daihatsu is working on "health management" and the top management and the labor union have a common recognition and are promoting it.

Health and productivity management promotion systems

Health and productivity management

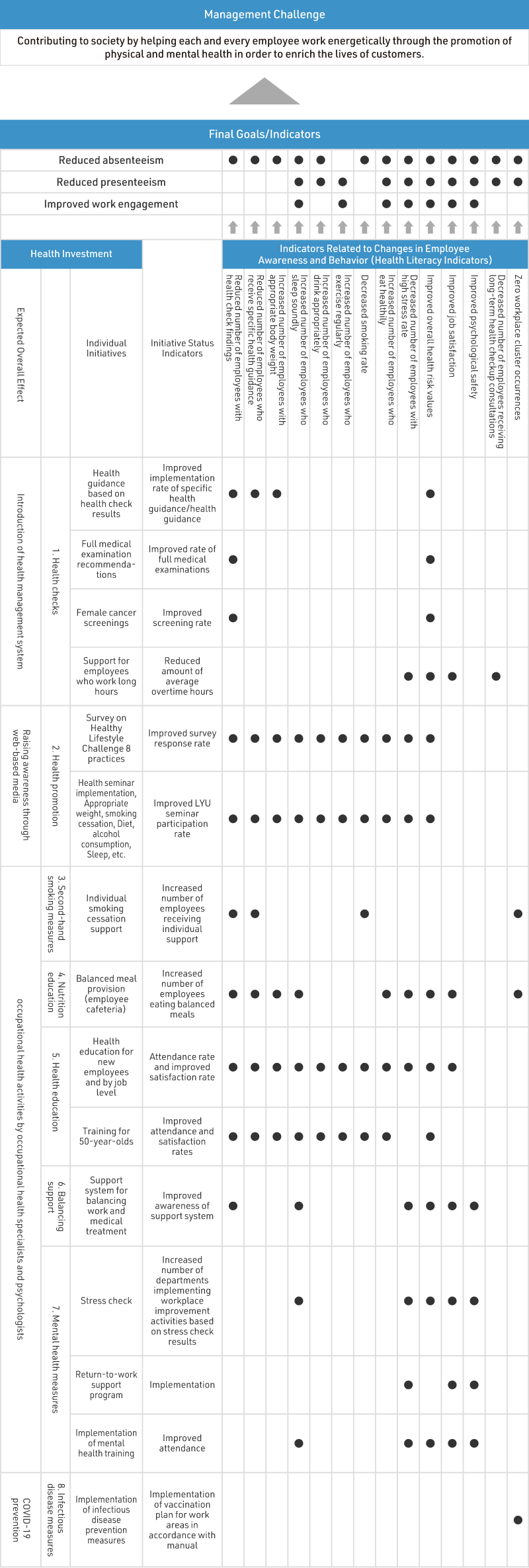

In the process of health management, we use existing health data (medical examination results, stress checks, etc.) to visualize the current situation. We have also clarified our health management targets and achievement process in a strategic map to achieve our management policy of "Enriching our lives by being close to our customers." We are also working to increase the momentum of these activities through the support of top management and to ensure that health management is widely accepted and firmly established.

We also encourage our business partners to promote healthy management by sharing the following points: (1) Importance of Healthy Management (2) How to Promote Healthy Management (3) Daihatsu's Initiatives and Effects.

1. Health and Productivity Management Strategy Map

Safety and health activities promoted jointly by labor and management

Labor and management are working together to create an attractive company and an attractive workplace.

After discussing specific measures at the "Workplace Meeting," a forum for discussion between labor and management at each workplace, each workplace takes the initiative in creating an environment where employees can work in a healthy manner both mentally and physically.

Health Measures

1. Health Checks

Health checks are the base of all health activities and improve health awareness (health literacy). At Daihatsu, health checks and health guidance are performed internally, and the company has established a system for collaborating with outside healthcare facilities to promote early detection and treatment of health-related conditions.

Regular health checks are conducted every year in each employee’s birth month and include not only the testing items specified in the Industrial Safety and Health Act, but also additional screenings for cancer and other conditions such as fecal occult blood tests (colon), ABC tests (stomach), sputum tests (lung), and echo tests (cervical/abdominal).

In addition, Daihatsu has also introduced PSA tests (prostate) for men and breast and uterine cancer screening for women.

Daihatsu Health Center (exterior)

Daihatsu Health Center (exterior)

Daihatsu Health Center

Daihatsu Health Center

(1st floor, health check floor)

2. Health Promotion

The foundation of good employee health is improved health awareness (health literacy) for each and every employee.

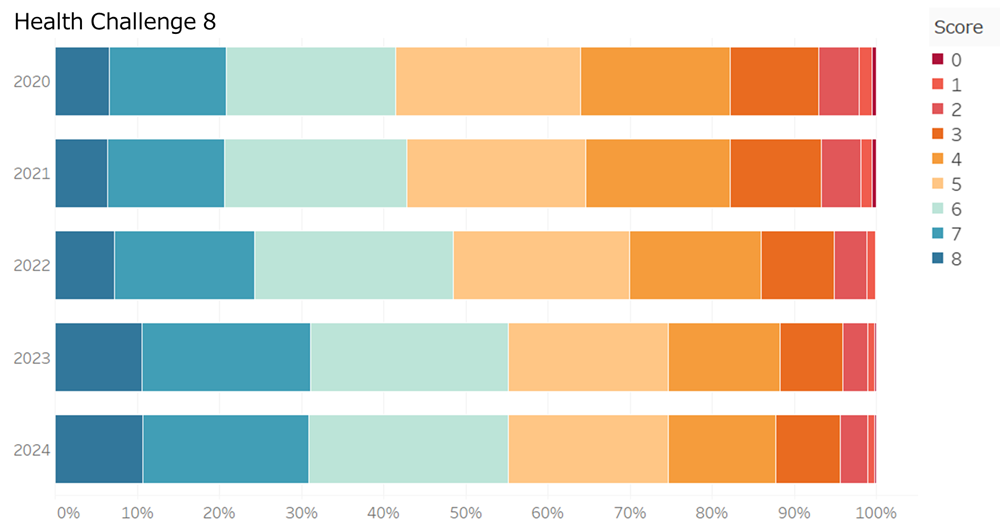

Daihatsu conducts a program known as “Healthy Lifestyle Challenge 8,” which seeks to improve health-related habits by focusing on eight habits that affect health. The company conducts surveys twice annually on the eight health-related habits of sleep, breakfast, snacking, appropriate weight, exercise, alcohol consumption, smoking, and stress, and implement the PDCA cycle to support voluntary and independent health promotion by employees.

In addition, Daihatsu also conducts workplace-based seminars led primarily by in-house industrial health staff and other instructors in order to support workplace-based health promotion activities.

Healthy Lifestyle Challenge 8

| □ 1. Sleep | I sleep well |

|---|---|

| □ 2. Breakfast | I eat breakfast everyday |

| □ 3. Snacks | I eat post-dinner, pre-bedtime snacks to twice a week or less |

| □ 4. Appropria te weight | I have a BMI of 25 or less |

| □ 5. Exercise | I exercise 30 minutes or more per day at least once per week |

| □ 6. Alcohol | I don't drink, or I drink two units of alcohol or less per day |

| □ 7. Smoking | I don't smoke or I am trying to give up |

| □ 8. Stress | I do not have high levels of stress |

Certified as a "Sports Yell Company 2025” by the Japan Sports Agency

Certified as a "Sports Yell Company 2025” by the Japan Sports Agency

Workplace-based health promotion activities

Workplace-based health promotion activities

Participation in a public-private partnership program of the Japan Sports Agency

Participation in a public-private partnership program of the Japan Sports Agency

3. Measures against passive smoking

Aiming to create a healthy and work-lasting workplace environment, we began ”no- smoking on the facilities/ on the premises” in fiscal 2024.

Smoking cessation seminar by industrial health staff

Smoking cessation seminar by industrial health staff

4. Dietary Education

Daihatsu is promoting dietary education at the employee cafeterias of each business site by providing balanced menus that satisfy certification standards (compliant with the “Smart Meal” program promoted by the Ministry of Health, Labour and Welfare). Labor and management, food service providers, human resources departments, and departments responsible for promoting safety and health are working together to promote employee health through dietary education. We have developed employee cafeterias with a variety of innovations such as the provision of balanced menus, aiming to enable employees to eat healthy meals.

Furthermore, Daihatsu also conducts seminars that address breakfasts and snacking, which are key to good health.

Sample of balanced menu on display at entrance of employee cafeteria

Sample of balanced menu on display at entrance of employee cafeteria

Logo of “Smart Meal” program promoted by the Ministry of Health, Labour and Welfare

Logo of “Smart Meal” program promoted by the Ministry of Health, Labour and Welfare

Dietary education seminars run by dieticians and public health nurses (web)

Dietary education seminars run by dieticians and public health nurses (web)

5. Health Education

Health education is provided systematically so that all employees can work in good health.(Examples: Training for new employees, training for newly appointed supervisors, and other health education for important milestones.)

In the health education at turning points, we provide education for 25, 30, and 36 to 64 years old (every 4 years) based on the appropriate BMI according to the health issues of each age group. In addition, the degree to which individual health targets set at the time of the training have been established is followed up six months later.

Health education run by public health nurses and clinical psychologists (at new employee training)

Health education run by public health nurses and clinical psychologists (at new employee training)

Physical fitness measurement by public health nurse (as part of health education at milestones)

Physical fitness measurement by public health nurse (as part of health education at milestones)

6. Support for Balancing Treatment and Work

In recent years, the number of people who working while continuing treatment for illness has been increasing, and guidelines have been established by the Ministry of Health, Labor and Welfare. This is because advance in diagnostic techniques and treatment methods are changing what was once considered an incurable disease into long-lasting illness.

Because cooperation with the workplace and medical institutions is essential for a balance between treatment and work, we are working to create a comfortable workplace environment so that employees do not have to choose to give up their work for treatment. We also provide special leaves, reduced working hours (4 -, 5 -, 6 -, and 7-hour shifts per day), and leaves for fertility treatments for those who have illness that require repeated or continuous treatment or infertility treatment. We also actively support work-life balance in childcare and nursing care.

<Topics>

Workplace supports return to work for employees with severe heart failure

We have created a support system for employees returning to work with a ventricular assist device (VAD) who have severe heart disease through collaboration among workplaces, workplace clinics, and the human resources department.

The following are the requirements for return to work for VAD recipients.

(1) The workplace should allow emergency vehicles to reach Osaka University, National Cerebral and Cardiovascular Center Hospital, etc. within 2 hours.

(2) Always have a supporter nearby who can respond to any equipment trouble that may occur.

Workplace members and occupational health staff learned how to handle the equipment and how to respond to emergencies, and after final confirmation by the physicians, coordinators, and others at the VAD implementation facility, the employee * in question was able to return to work. This initiative was awarded the 14th GP Incentive Award by the Japan Society for Occupational Health as a highly creative and applicable workplace example.

* The employee in question had a successful transplant surgery and has already returned to work.

Employee receiving advice from full-time occupational health physician (image)

Employee receiving advice from full-time occupational health physician (image)

Ministry of Health, Labour and Welfare character

Ministry of Health, Labour and Welfare character

7. Mental Health Measures

Occupational health personnel including occupational physicians, psychologists, and public health nurses provide specialized support for the development of healthier work environments and the early detection and prevention of recurrence of mental health issues.

As a preventative measure, employees who are determined to be experiencing high levels of stress through annual stress checks undergo individual interviews with an occupational physician, and feedback on the results of organizational analysis is provided to worksites.

Daihatsu also plans and conducts mental health training intended to enhance self-care and care provided by managers and supervisors.

We have established an in-house mental health consultation desk where employees can consult at any time so that they can work with peace of mind without having to worry about anything. We also provide support for those who are absent from work due to mental disorders to return to work.

In addition, the EAP service has been introduced, and a system has been established to allow consultation with outside experts.

Occupational health staff serving as instructors to conduct training

Occupational health staff serving as instructors to conduct training

Health consultation waiting room

Health consultation waiting room

Health consultation room

Health consultation room

8. Infectious Disease Measures

We are creating and continually updating internal standards to prevent infection and the spread of infection.

In addition, with the aim of creating a workplace where people can work with peace of mind, our industrial health staff work closely with employees to provide support.

Even after the COVID-19 outbreak has been classified as Category 5 under the Infectious Diseases Control Act, we continue to encourage hand disinfection, ventilation, etc., and are working towards zero outbreaks of infection in the workplace.