- Company

- Management Policy & Strategy

- Technology

- NEWNov. 13, 2025

Daihatsu Metal and Daihatsu Jointly Develop Biomass Fuel and Begin Use in Cupola Furnace - Promoting a regionally coordinated effort aimed at achieving carbon neutrality -

Nov. 13, 2025

DAIHATSU METAL Co.,Ltd.

DAIHATSU MOTOR CO., LTD.

Cupola furnace

Cupola furnace

Bio briquette

Bio briquette

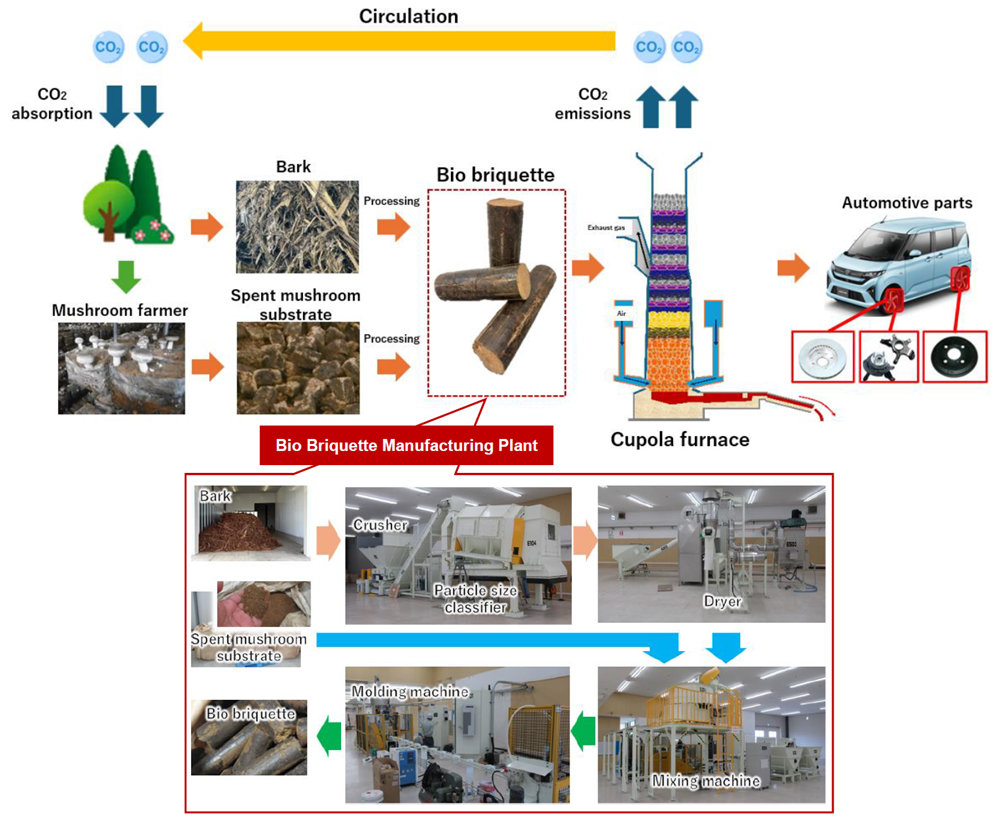

Daihatsu Metal Co., Ltd. (hereafter "Daihatsu Metal") has, together with Daihatsu Motor Co., Ltd. (hereafter "Daihatsu"), developed and established manufacturing technology for a carbon neutral biomass fuel called "bio briquette*" and begun using it in the cupola furnace, the melting equipment at the Izumo Plant of Daihatsu Metal.

Daihatsu Metal and Daihatsu are working to reduce CO2 emissions from the casting process as an initiative toward achieving carbon neutrality in factory production by 2035.

Daihatsu Metal joined the Cupola CN Co-creation Working Group in March 2023, a group composed of volunteer companies and organizations, for the purpose of reducing CO2 emitted when melting iron in the cupola. The company has carried out research and development of biomass fuels, established manufacturing methods, and conducted information exchange and surveys related to raw material procurement.

Since 2024, Daihatsu Metal has jointly conducted research on bio briquettes using regional resources such as spent mushroom substrate and bark as a biomass fuel to replace coke derived from coal. Now, using the technology established by Koyama Co., Ltd., a member of the working group, the company has established a manufacturing plant. In addition, by collaborating with local governments and companies in the region, Daihatsu Metal has created a system that can stably procure resources from the region and constructed an integrated energy circulation model that covers everything from resource procurement to manufacturing and utilization of biomass fuel.

Daihatsu Metal will gradually raise the replacement rate of bio briquettes and, in the future, also work on utilizing a variety of biomass fuels, aiming for a 100 percent replacement rate (no use of coke) by 2035.

Going forward, Daihatsu Metal and Daihatsu will continue to promote initiatives toward carbon neutrality with the aim of regional revitalization and realization of environmentally friendly foundries, thereby contributing to the creation of sustainable local communities.

*Bio briquette: a solid fuel made by compressing biomass resources such as wood and plant fibers

Summary of the Initiative

Process flow of a bio briquette manufacturing plant

(1) Collection of biomass resources and preparation for processing

- Bark is delivered peeled from the wood and subsequently crushed into smaller pieces with a crusher and dried.

- Spent mushroom substrate is delivered in a crushed and dried state.

(2) Processing biomass resources into bio briquettes

- The prepared bark and spent mushroom substrate are loaded into the mixing machine tank and mixed.

- The material is solidified and formed into rod shape by a molding machine, then cut to the specified size to complete processing