- Company

- Management Policy & Strategy

- Technology

- NEWOct. 07, 2025

DAIHATSU, TCRDL, and TOYOTA KYUSHU Collaborate to Start Field-test for a Microgrid System Utilizing Renewable Energy

Oct. 07, 2025

DAIHATSU MOTOR CO., LTD.

TOYOTA CENTRAL R&D LABS., INC.

TOYOTA MOTOR KYUSHU, INC.

The three Toyota Group companies DAIHATSU MOTOR CO., LTD. (Ikeda City, Osaka Prefecture; President: Masahiro Inoue; hereinafter “DAIHATSU”), TOYOTA CENTRAL R&D LABS., INC. (Nagakute City, Aichi Prefecture; President and Chief Research Officer: Takashi Shimazu ; hereinafter “TCRDL”), and TOYOTA MOTOR KYUSHU, INC. (Miyawaka City, Fukuoka Prefecture; President and Member of the Board of Directors: Tetsuro Choki; hereinafter “TOYOTA KYUSHU”) have started field-test for a microgrid system utilizing renewable energy at the TOYOTA KYUSHU Kokura Plant in October 2025.

1. Background

Effectively utilizing renewable energy sources such as solar power and biomass has become essential for achieving carbon neutrality in recent years.

DAIHATSU is focusing on microgrid systems, which are effective for the local production and consumption of renewable energy. It has collaborated with TCRDL to jointly develop a high-efficiency electronic power converter (name: Smart Power Hub® , hereinafter “SPH”®)*1. This converter is capable of minimizing energy loss when converting electricity generated from renewable sources. DAIHATSU has been verifying the technology internally since last year, but confirming its effectiveness and reliability in large-scale use environments has been a challenge for its practical application.

At the same time, TOYOTA KYUSHU has been working to achieve carbon neutrality by actively using renewable energy. This includes producing hydrogen using green electricity generated by solar power and using it in its plants, as well as developing storage batteries (KRe:Ba) *2 that reuse batteries and other parts from hybrid vehicles. However, improving the efficiency of electricity conversion and ensuring stable operation has been a challenge for utilizing renewable energy more effectively.

2. Overview

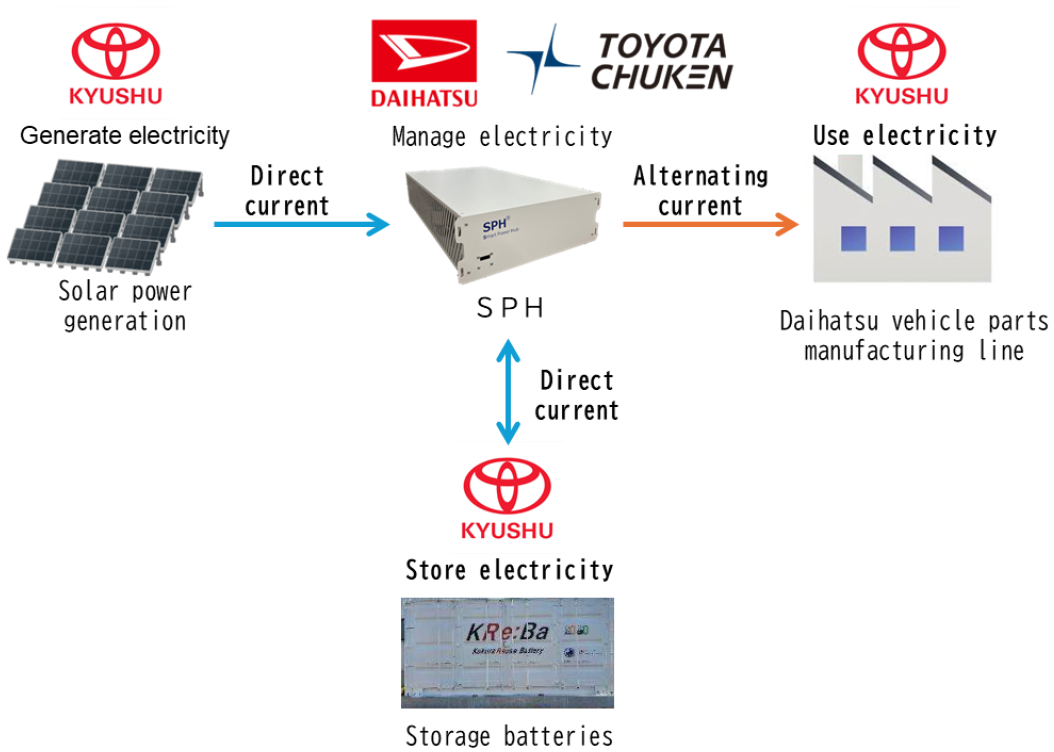

As part of this field-test, a microgrid system that efficiently utilizes electricity was built at TOYOTA KYUSHU Kokura Plant. This system uses the SPH jointly developed by TCRDL and DAIHATSU to supply electricity generated by solar power to the parts manufacturing line, while storing surplus electricity in storage batteries. The effectiveness and reliability of the system will be confirmed through verification with an actual operating manufacturing line. In the future, this system will contribute to reducing CO2 emissions by enabling the local production and consumption of energy, as well as peak shifting, where electricity stored during the day is used at night.

<Advantages of the microgrid system>

- The SPH , a newly developed 3-port electronic power converter (connecting three directions: power generation, storage, and consumption), enables an efficient DC based microgrid system. It reduces the number of DC/AC conversions compared to conventional AC based systems, reducing energy loss by approximately 45%.

- It achieves a low-cost and compact design by using and modifying existing automobile parts like inverters for compact electrified vehicles. It can also be installed in small-scale facilities.

- Ultra-high-speed control (over 1,000 times per second) enables electricity from storage batteries to be instantly supplied when power generation from renewable sources drops This ensures continuous electricity supply even during momentary power outages, preventing risks such as production interruptions and data loss.

(Diagram of the microgrid system)

3. Future developments

The Toyota Group aims to reach net-zero CO2 emissions at its global plants by 2035, thereby achieving carbon neutrality.

DAIHATSU, TCRDL, and TOYOTA KYUSHU will continue to work hard together and accelerate efforts toward carbon neutrality in order to help realize a sustainable society.

4. Comments from each company

Comment from Masanori Kuwata, Executive Vice President of DAIHATSU MOTOR CO., LTD.

I am very pleased that three Toyota Group companies have collaborated to begin field-test of a microgrid system. This project leverages the strengths of each company: TCRDL 's elemental technology development capabilities, TOYOTA KYUSHU's expertise in utilizing renewable energy, and DAIHATSU's technology and know-how for producing high-quality cars at affordable prices.

We will accelerate our efforts toward achieving carbon neutrality with an eye toward eventually expanding the know-how in renewable energy utilization gained from this project to other plants, outlets, and small-scale business sites.

Comment from Toshitaka Tanabe, Executive Officer of TOYOTA CENTRAL R&D LABS., INC.

SPH is an electricity conversion technology unique to the Toyota Group. It was created by applying power electronics technology cultivated in electrified vehicle development to microgrids. I am very pleased that SPH, which encourages the use of renewable energy such as solar power generation, has taken a step toward social implementation through this field-test. As the central laboratory driving research and development across the Toyota Group, we will continue developing elemental technologies that contribute to solving social issues.

Comment from Nobutaka Iwahara, Executive Vice President and Member of the Board of Directors of TOYOTA MOTOR KYUSHU, INC.

We are very honored to be conducting this field-test together with our Toyota Group partners at the Kokura Plant, where we are working to conducting technology demonstrations using solar power, energy storage systems, fuel cells as we aim for carbon neutrality at our plants by 2035. We will utilize the expertise gained from this field-test to effectively utilize renewable energy and contribute to realizing a sustainable society.

*1 "Smart Power Hub" and "SPH" are registered trademarks of TOYOTA CENTRAL R&D LABS., INC.

*2 "KRe:Ba" is a coined term combining the "K" from the Kokura Plant and "Re:Ba," an abbreviation of "reuse battery." It refers to storage batteries assembled from used batteries of automobiles and forklifts.