- Company

- Overseas

- Management Policy & Strategy

- NEWFeb. 27, 2025

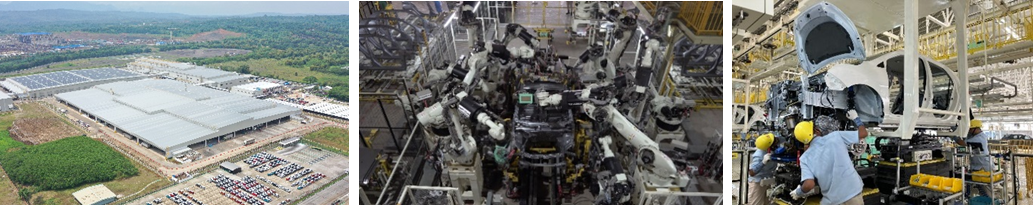

Daihatsu Commences Operations of New Assembly Plant in Indonesia ~Introducing the most advanced technologies in environmental and production efficiency and accelerating the strengthening of the Daihatsu Group’s competitiveness~

Feb. 27, 2025

DAIHATSU MOTOR CO., LTD.

PT Astra Daihatsu Motor (ADM), an Indonesian subsidiary of DAIHATSU MOTOR CO., LTD. (hereinafter “Daihatsu”) has commenced full-scale operations of the Karawang Assembly Plant 2, which incorporates the most advanced technologies in environmental and production efficiency, and held an opening ceremony today.

In anticipation of the aging of the ADM Sunter Assembly Plant 1, which has been in operation for 27 years, and of future carbon neutrality measures, Daihatsu has been renewing the Karawang Assembly Plant 2 since February 2023. The concept is E-SSC*1, a further evolution of SSC (simple, slim, and compact), Daihatsu’s MONODUKURI concept. By introducing the most advanced production technologies in environmental and production efficiency in the welding, painting, and assembly processes with a focus on the innovative technologies adopted at the Kyoto (Oyamazaki) Plant, which was refined in 2022, Daihatsu will increase its competitiveness, and through measures including the installation of solar panels on the roof of the plant building, reduce CO2 emissions by approximately 30% per year.

The Karawang Assembly Plant, which commenced operations in 2013, has delivered a cumulative total of approximately 2.3 million units of vehicles to customers in Indonesia and around the world as a vehicle production base for the Toyota Group. With this renewal, the Karawang Assembly Plant has become the Daihatsu Group’s largest vehicle production plant overseas, with an annual production capacity of 360,000 units.

Daihatsu will further deploy the expertise and technologies developed in this process and expand to plants in Japan and overseas to strengthen the competitiveness of the Daihatsu Group and accelerate its initiatives to become carbon neutral in production. At the same time, by refining its manufacturing of high-quality and affordable cars that are close to the customers’ lifestyles in Indonesia and other regions, Daihatsu will contribute to the growth of the automobile industry and the human resource development in each region.

*1 The “E” in E-SSC stands for “Evolution.”

<Overview of the new plant (Karawang Assembly Plant 2) >

| Location | Suryacipta City of Industry, Karawang, West Java Province, Indonesia |

|---|---|

| Site area | 224,529 m2 (total of Karawang Assembly Plant: 940,012 m2) |

| Building area | 71,953 m2 (total of Karawang Assembly Plant: 264,085 m2) |

| Investment | 2,900 billion rupiah* (approx. 26.7 billion yen) *Note: Converted at the rate 1 rupiah = 0.0097 yen (as of February 20, 2025) |

| Commencement of operations | December 2024 |

| Production capacity | 140,000 vehicles/year (total for ADM: 530,000 vehicles/year (no changeover) |

| Number of employees | Approx. 700 (as of December 2024) |

| Processes to be renewed | Body (welding), painting, assembly, etc. |

| Vehicles produced | Daihatsu Ayla/Toyota Agya/Toyota Wigo (as of February 2025) |

<Main characteristics of the new plant>

1. Overall concept

- While achieving high productivity and high quality, establish a locally optimized plant that contributes to carbon neutrality in Indonesia through excellent environmental performance.

- Launching a new plant led mainly by ADM’s production technology national staff. It can be seen as the result of Daihatsu’s efforts to promote local employment and human resource development, thereby the number of support man-hours by Daihatsu’s production technology staff are reduced by 60% from the time of construction of the Karawang Assembly Plant 1.

- Introduce new facilities for the future production of electrified vehicles while expecting the installation of approximately 5,100 solar panels for 3,000 kW of power on the roof of the plants*2 and the introduction of the new technologies in each process to reduce CO2 emissions by 30% compared to that of the ADM Sunter Assembly Plant 1.

- Enhance an efficient plant layout based on parts logistics while ensuring safety by separating the flow lines between employees and vehicles, including trucks.

*2 Total number of solar panels installed at the Karawang Vehicle Plant Line 1 and Line 2.

2. Welding process

- By increasing the number of robots introduced for spot welding, improve the automation rate and achieve both quality improvement and labor savings. Furthermore, by concentrating the placement of robots, accelerating their speed, and introducing the most advanced robots each capable of performing multiple welding tasks, achieve the minimum number of processes at Daihatsu plants.

3. Painting process

- Fully deploy environmental and efficiency technologies adopted at the Kyoto (Oyamazaki) Plant.

- Implement dry booths with cardboard filters and adopt machines with high coating efficiency using electrostatic induction technology. In addition, achieve efficient heat management by concentrating heat source processes on the third floor.

4. Assembly process/logistics

- Improve efficiency of parts logistics by achieving a layout that enables parts to be supplied from four directions around the assembly line. In addition to securing flow lines for logistics trucks, shorten transport distances by increasing the proximity between parts storage areas and production lines.

- Achieve “people friendly” work processes based on ergonomics. Like at the Kyoto (Oyamazaki) Plant, by adopting a method where the heavy and large parts are loaded while the vehicle is stopped, achieve both a reduction of load on workers and quality improvement.

- Improve air circulation in the plant by providing natural ventilation through the “wall-less” layout, which removes part of the outer wall of the parts receiving space. Contribute to the reduction of CO2 emissions as well by reducing the utilization rate of air conditioning equipment.

- In anticipation of the future production of electrified vehicles, introduce transfer equipment capable of handling heavy parts such as batteries.

<Overview of ADM>

| Company name | PT Astra Daihatsu Motor |

|---|---|

| Location | Sunter, Jakarta |

| Number of employees | 10,367 (as of January 2025) |

| Representative | President Director Yasushi Kyoda |

| Establishment | 1992 |

| Commencement of production | January 1992 |

| Production capacity | 530,000 vehicles/year |

| Number of production units (FY 2023) |

467,126 units (year-on-year: 85.2%) Daihatsu vehicles: 181,568 units (88%) /OEM vehicles (Toyota, Mazda): 285,558 units (83.5%) |

| Number of production units (January to December, 2024) |

428,460 units (year-on-year: 85.0%) |

| Sales volume (FY 2023) | 185,688 units (year-on-year: 93.2%) |

| Sales volume | 168,263 units (year-on-year: 86.7%) |

| Cumulative production | Approx. 8,000,000 units |

| Sales amount | Not disclosed |

| Investment ratio | Daihatsu Motor: 61.76% Astra International: 31.87% Toyota Tsusho: 6.37% |