- Notification

- SDGs /CSR /Environment

- NEWDec. 23, 2022

Daihatsu Receives Promotion of Machine Industry Prize for Development of High-Performance Dry Filter for Paint Booths ~Achieving 45% Reduction in CO2 Emissions for the Entire Paint Booth~

Dec. 23, 2022

Daihatsu Motor Co., Ltd.

Daihatsu Motor Co., Ltd. (hereinafter “Daihatsu”) announced today that it has received the Encouragement Prize in the 57th Promotion of Machine Industry Prizes sponsored by the Japan Society for the Promotion of Machine Industry, in recognition of the development of a high-performance dry filter for paint booths.

The Promotion of Machine Industry Prizes are given to companies, universities, research institutes, support organizations, and development/support personnel that have made a remarkable contribution to the technological advancement of Japan's machine industry through outstanding development, application, and supporting activities.

Awarded Accomplishments

Development of a high-performance dry filter for paint booths

Overview

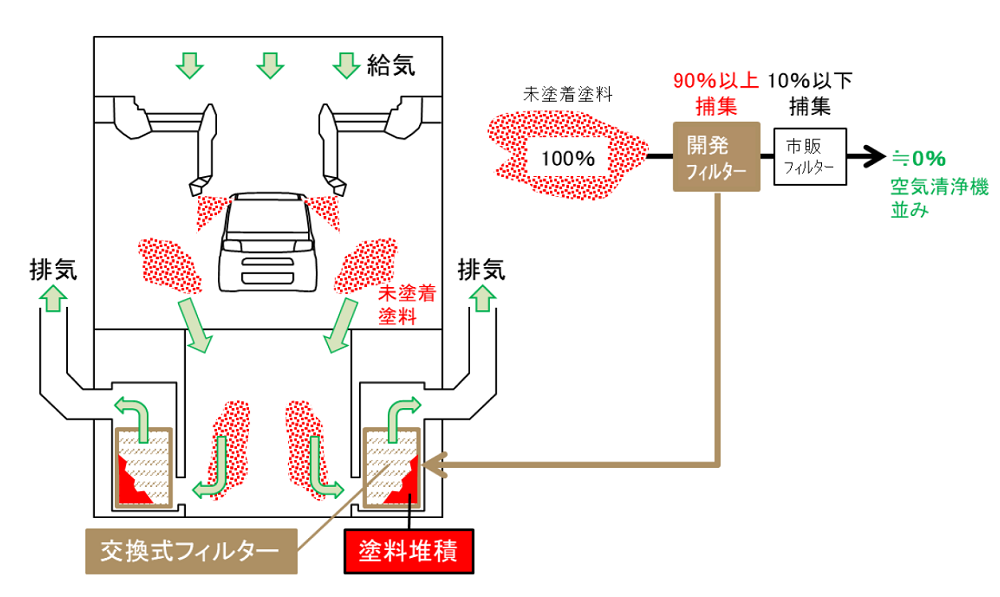

Toward the goal of achieving carbon neutrality at its plants by 2035, Daihatsu is working to reduce CO2 emissions from its production facilities. Among the production facilities, the paint booths account for the highest amount of CO2 emissions, and while there are ways to reduce CO2 emissions such as reducing the amount of airflow in air conditioning, as well as using air-conditioned recycling technology upon changing the method of capturing uncoated paint from a wet scrubber system to a dry scrubber system, it was difficult to achieve both uncoated paint removal efficiency and a long replacement cycle with existing filters, and there were no inexpensive filters available.

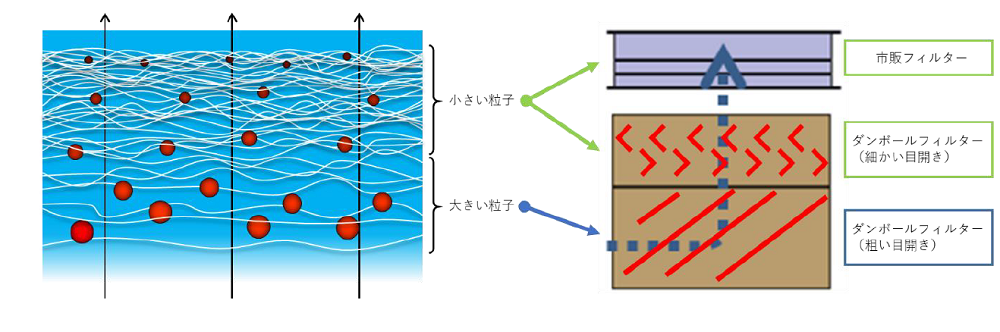

The newly developed replaceable dry filter (see Fig. 1) uses cardboard as an inexpensive material, and optimizes the structure of the filter material for each type of paint based on the concept of depth filtration (see Fig. 2), making it possible to achieve both removal efficiency and a long replacement cycle. As a result, CO2 emissions for the entire paint booth were reduced by 45% and maintenance costs by more than 50%. In addition, the new system eliminates water usage, extending the facility's service life, and reducing the odor and noise associated with water usage, resulting in an improved working environment.

[Figure 1: Replaceable dry filter]

[Figure 2: Depth filtration]

Daihatsu will continue to pursue the realization of carbon neutrality at its plants by 2035 through thorough implementation of energy conservation measures.