Fundamental Approach / Environmental Management Structure / Daihatsu Group Initiatives

-

Fundamental Approach / Environmental Management Structure / Daihatsu Group Initiatives

-

Management of Environmental Load Substances in Production Activities / Management of Water Resources / Chemical Substances and Risk Management

-

Environment Month Events / Environmental Education

-

Daihatsu Environmental Communication System / Environmental Communication with Local Communities

Fundamental Approach

The Daihatsu Group carries out environmental conservation activities with the goal of eliminating environmental accidents and complaints as well as compliance violations. To achieve this goal, we have adopted the ISO 14001 international standards for environmental management systems. All affiliated companies in Japan and overseas act in accordance with the structures of these ISO 14001 compliant environmental management systems and seek to earn the trust of the local communities in which they operate.

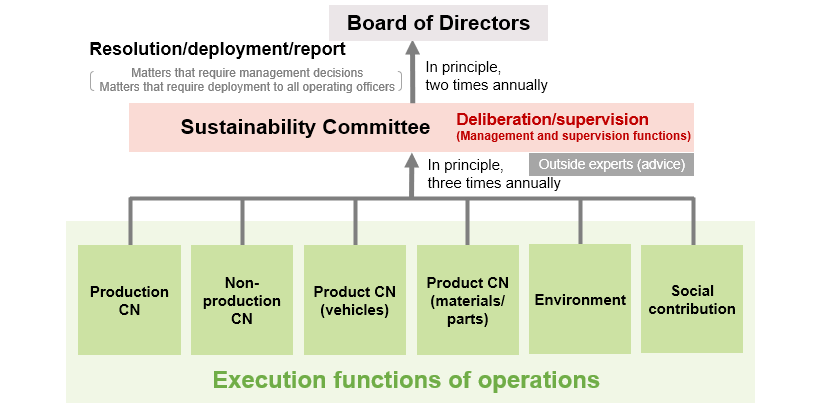

Environmental Management Structure

Daihatsu is reinforcing company-wide environmental management under the leadership of the Sustainability Committee, which is chaired by the executive vice president and whose membership includes chief officers and Audit & Supervisory Board members. We are focusing on environmental management initiatives set out in the Seventh Daihatsu Environmental Action Plan.

Structure of Implementing Bodies

| Sustainability Meeting | |

|---|---|

| Chairman | Executive Vice President |

| Members | All chief officers of all business groups and major overseas production sites |

Environmental Management Process

Daihatsu established the Sustainability Committee to disseminate policies for Daihatsu and its consolidated affiliated companies and carry out sustainability initiatives throughout the Daihatsu Group. The committee also plays an important role in promoting action by supervising the status of implementation of sustainability initiatives within the Group. In principle, the committee meets three times annually. Described below are the details of the committee’s specific actions.

- Propose sustainability policies for the Daihatsu Group and disseminate them to Daihatsu and affiliated companies. Also, supervise the status of implementation of initiatives in conjunction with policy reviews.

- In cases where the sustainability policies and initiatives of Daihatsu and our affiliated companies are contrary to or deviate from global conditions and social trends, request reexamination of those policies and initiatives. To this end, receive advice and so on from outside expert organizations and monitor global conditions and social trends at all times.

- Following deliberation on matters referred to the committee, the chairperson makes a determination whether improvement is needed, and if so, the committee issues instructions for improvement.

- Regularly report on the details of initiatives to the Board of Directors, in principle, twice annually.

Support for Establishing Environmental Management Systems

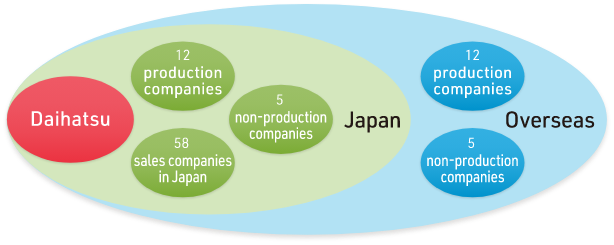

The Daihatsu Group strives to prevent environmental accidents and complaints and to ensure legal compliance in accordance with our environmental management systems, which is compliant with ISO 14001. Daihatsu recommends the introduction of environmental management systems not only by production companies subject to environmental consolidation, but also by companies with which we have capital relationships and priority production companies and supports their activities to acquire certification if requested. As of fiscal 2022, all production companies subject to environmental consolidation in Japan have acquired ISO 14001 certification and continue to renew and maintain it. All our production subsidiaries have updated their environmental management systems to the 2015 version of ISO 14001, which reinforced the leadership responsibility of top management. Daihatsu also provides support for the introduction of ISO 14001 by overseas production subsidiaries.

Scope of Environmental Management

The environmental load generated by Daihatsu’s business activities includes those from subsidiaries and business partners; for this reason, the entire Daihatsu Group must implement environmental conservation activities. We categorize affiliated companies based on their capital relationship and business type, and promote environmental management for the entire Group accordingly. As a specific measure, Daihatsu hosts Group-wide environmental liaison meetings twice a year to encourage Group companies to share various forms of environmental information and to facilitate Group companies learning from one another. Going forward, we will shift from Japan-centric meetings to global environmental meetings.

Environmental Activities by Sales Companies in Japan*

“Daihatsu Clean Management Dealer” Certification System

Dealers that have satisfied the requirements of the comprehensive inspection (self-assessment) can apply to become Daihatsu Clean Management Dealers. Under this system, Daihatsu auditors carry out on-site assessments of the applicants’ environmental management structures and environmental conservation activities and certify those that satisfy the requirements of the assessments as Daihatsu Clean Management Dealers. The certification is valid for three years; during this period, dealers reinforce their environmental activities through PDCA cycles—such as by carrying out annual self-assessments and implementing improvements as necessary. Going forward, we will endeavor to improve and enhance the environmental performance of our dealers.

Carbon Neutrality Initiatives

Sales companies in Japan have been collecting monthly energy usage data since 2005 to ascertain their CO2 emissions. To support these efforts, Daihatsu creates and distributes energy saving manuals for sales companies. In addition, in 2022 sales companies began full-scale efforts to achieve carbon neutrality.

* All domestic sales companies regardless of investment ratio

Green Procurement Guidelines

In line with the Daihatsu Environmental Action Plan, the Daihatsu Green Procurement Guidelines address a wide variety of environmental issues that should be of importance to companies, and Daihatsu is greatly expanding and enhancing the details.

To ensure that our business activities are even more in harmony with the global environment in the future, the cooperation of business partners is crucial, and we will request that business partners take action in accordance with the Guidelines.