Initiatives for Logistics

-

Fundamental Approach and Targets

-

Initiatives for Products

-

Initiatives for Production

-

Initiatives for Non-production

-

Initiatives for Logistics

Reducing CO2 Emissions of Consolidated Logistics Companies by 10% by 2035

In 2022, the Daihatsu Group established a specialized organization to promote significant reductions in CO2 emissions across our logistics operations, and we are committed to taking even greater action than before. Our aim is to reduce the CO2 emissions of our consolidated logistics subsidiaries by 10% by 2035 through the implementation of various effective measures.

Reducing CO2 Emissions in Logistics

The subsidiary responsible for parts transportation is introducing large hybrid electric trucks and electric forklifts in stages

The subsidiary responsible for parts transportation is introducing large hybrid electric trucks and electric forklifts in stages

In order to reduce the carbon footprint of our logistics subsidiaries, we are replacing fossil-fueled forklifts with electric-powered ones and replacing large trucks with hybrid electric vehicles for parts transportation in stages. As for completed vehicle transportations, we are also working to improve the loading efficiency of car carriers and replace the tractor heads with the latest fuel-efficient vehicles. In addition, we are dedicated to implementing various measures to increase logistics efficiency, such as modal shifts and co-creation of shared transportation systems with other companies, to further reduce our CO2 emissions in the future.

Modal Shift to Railroad Transportation Using the Unique Characteristics of Small Cars

Daihatsu’s core products are mini-vehicles measuring 3.4 meters or less in length that fit into a railroad container. Taking advantage of this unique characteristic, since 1996 Daihatsu has been transporting them between Kyoto Freight Station (Umekoji) and Niigata Freight Terminal Station by rail, which emits less CO2 compared to track transportations. In 2016, in order to further expand our routes, we started developing loading methods using their self-propelling ability and specialized fixtures for transporting in containers, then putting them into operation since 2018.

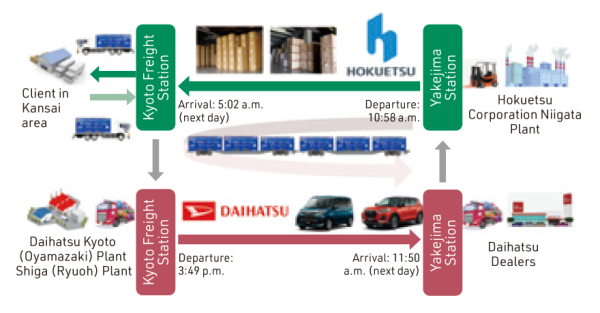

Additionally, in February 2025, through collaboration with the Hokuetsu Corporation, Nippon Express Co., Ltd., and the Japan Freight Railway Company, Daihatsu launched cross-industry backhaul matching rail transport (called “round matching” in Japan) for compact vehicles, aimed at achieving stable logistics capacity while also reducing environmental burden. Backhaul matching is a logistics method wherein a container is reused after delivery of freight to its destination by filling the container with additional freight to carry back to its point of origin, rather than sending it back empty. This increases container utilization rates, reduces environmental impact, and helps cut costs as well. Daihatsu uses this method in parts of its logistics network in which it transports small vehicles produced at the Kyoto (Oyamazaki) Plant and Shiga (Ryuoh) Plant to a sales company in the Niigata area.

Going forward, we plan to continue developing new routes.

Example of cross-industry backhaul (round) matching transportation

Railroad Transportation Routes

Eight routes

• Kyoto Freight Station to Niigata Freight Terminal Station

• Kitakyushu Freight Terminal Station to Toyama Freight Station

• Kitakyushu Freight Terminal Station to Minami-matsumoto Freight Station

• Fukuoka Freight Terminal Station to Niigata Freight Terminal Station

• Fukuoka Freight Terminal Station to Kita-nagano Station

• Kitakyushu Freight Terminal Station to Kanazawa Station

• Kitakyushu Freight Terminal Station to Niigata Freight Terminal Station

• Kyoto Freight Station to Niigata Yakejima Station

At the Hokuetsu Corporation Niigata Plant

At the Hokuetsu Corporation Niigata Plant