Carbon neutrality is a global goal to be achieved by the year 2050.

There is a demand to reduce CO2 emissions not only from the automobiles themselves, but also from the manufacturing process.

Did you know that Daihatsu is actually working to achieve carbon neutrality through an initiative that is rare, even on a global basis?

The key is cattle dung from cattle fattened in Ryuo Town, Shiga Prefecture!

Yoshimi Iwamoto of the Inner Communication Group introduces the people involved in the Ryuo Biogas Project, Daihatsu’s unique initiative, and their thoughts on the project.

The Ryuo Biogas Project Story

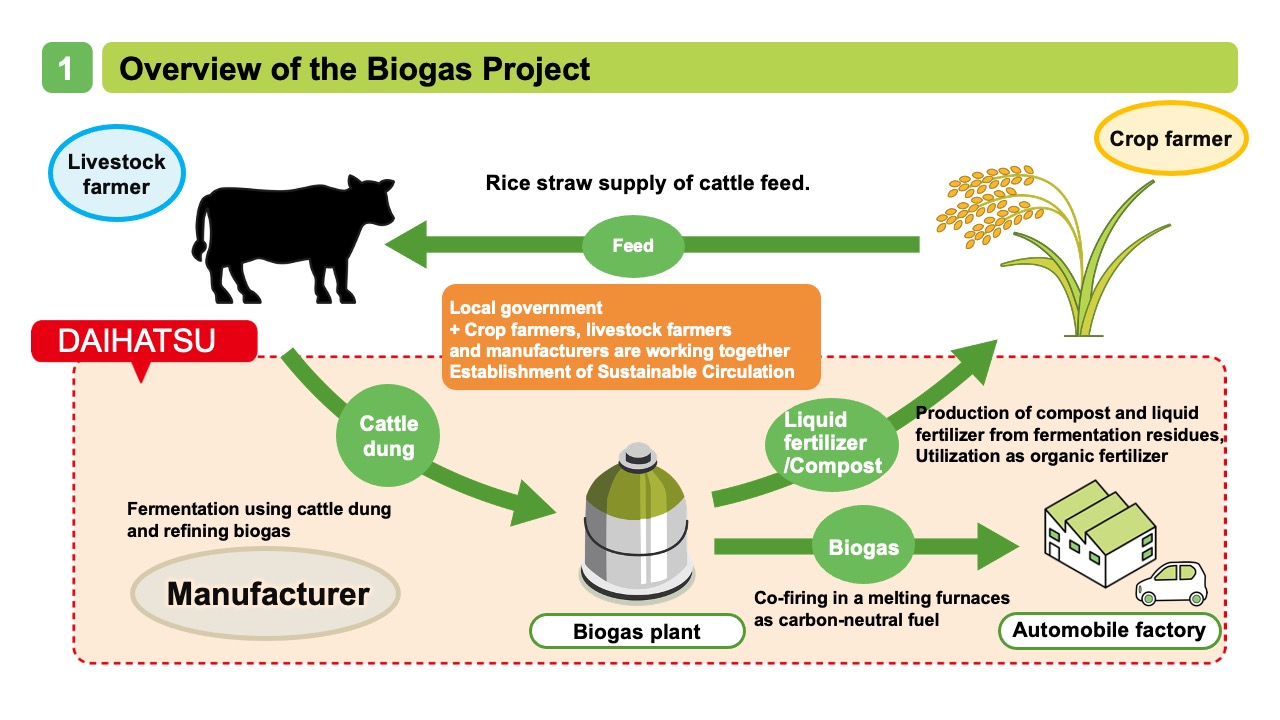

The Ryuo Biogas Project is an initiative to realize the Ryuo Town Biomass Industrial City Concept to create new resources and energy through a collaboration among crop farmers, livestock farmers (of Omi Beef), and the manufacturer (Daihatsu), which operate in Ryuo Town, Shiga Prefecture.

For more details, please see the video on the Ryuo Town website (reference).

In the Ryuo Town Biomass Industrial City Concept, Daihatsu is promoting the Ryuo Town Biogas Project, which involves creating biogas, an environmentally friendly fuel, from cattle dung and utilizing it as a heat source for automobile manufacturing.

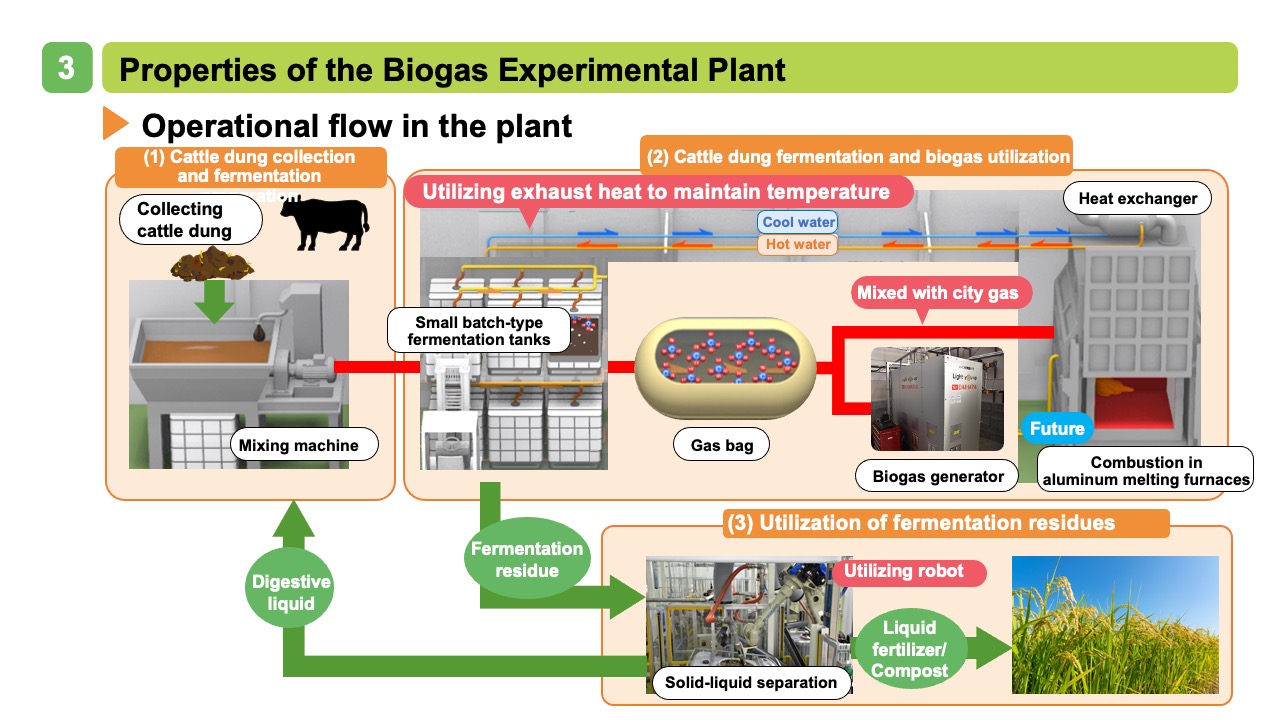

The process of using low-moisture dung obtained from Japanese wagyu cattle fattening methods as a raw material and fermenting it into biogas within a manufacturing plant is rarely seen anywhere else in the world.

Resource Circulation Through a Collaboration by Agriculture and Industry

Resource Circulation Through a Collaboration by Agriculture and Industry

This project involves three-way satisfaction between crop farmers, livestock farmers, and the manufacturer. It aims to create an environmentally friendly and sustainable local community.

Mechanism of the Bioplant

Mechanism of the Bioplant

For more details on the process, please see the video below.

The Creator of Innovative Ideas

Yasushi Oba of the BR Bio Project Department was looking for a method to create renewable energy to achieve decarbonization.

He thought it might be possible to produce gas from the dung of Omi cattle fattened in Shiga Prefecture and went to talk to Sawai Ranch’s President Takao Sawai himself, which led to the start of this project!

So they were able to get to where they are today through many failures!

We asked everyone involved in the launch of the initiative what their thoughts were while working on it, including their failures and hardships.

Biogas plant experiment room

Biogas plant experiment room

“Partners” Who Supported This Unprecedented Initiative

The BR Bio Project Department is an organization made up of people with diverse careers, such as in plants, production technology, development, and sales.

The project was made possible by their collective efforts, and we would like to introduce four of them here!

Nobuhiko Furuta - Worked on the Development of the Experimental Plant

The plant is now well equipped and outstanding, but when Mr. Furuta first arrived, there was nothing, and he started with cementing gravel on the floor. We asked him to tell us about his failures and hardships.

This equipment is for keeping the fermenter warm. Commercial products such as a large oven could be used as a substitute, but they are expensive and energy-consuming, so we made our own. At first, we made a prototype with a simple structure of hot water pipes running through the floor and surrounded by plywood. However, it did not perform well enough, so we placed simple heat storage materials made from hot water in plastic bags over the hot water pipes and attached insulation materials manually… Little by little, after repeated trial and error, the current form was completed.

Mr. Furuta also mentioned other equipment that was introduced after on-site visits to facilities deep in the mountains of Hokkaido and Kochi Prefecture, as well as robots and conveyors that had been idle at the plant and were converted with an adventurous spirit. “Every process has its own story of failure and hardship,” he said enthusiastically.

But despite all these failures and hardships, he says he has been “excited” about this project ever since he joined it. Why is that?

I want to bring this new challenge to fruition! That is my sole intention. I have been working on new projects in various departments, but it is very difficult to make them work as businesses. This project is still in the experimental phase. I am still going through trial and error with my team members every day, trying to reduce costs and improve the machinery!

From the left: Nobuhiko Furuta, Naoki Nakayama, and Yoshikazu Iseki

From the left: Nobuhiko Furuta, Naoki Nakayama, and Yoshikazu Iseki

Kenji Tani - Participated in the Development of the Plant from a Manufacturing Perspective

Currently, Mr. Tani is involved in a wide range of activities, including plant operation and the study of compost and liquid fertilizer usage. We asked him to tell us about his commitment to plant development.

In the process of turning cattle dung into biogas and fertilizer, we were particular about keeping the traffic flow of workers at the shortest distance and with the least waste.

Daihatsu’s Simple, Slim, and Compact (SSC)* concept has come alive here! The work that initially required two people can now be done with by just one person, thanks to a lot of ingenuity!

We asked him to tell us about any other hardships encountered.

* The basis for Daihatsu’s work methods and ways of thinking, which involve making equipment and processes simple, slim, and compact to increase efficiency.

In the early days of development, I had to go to Sawai Ranch to pick up 300 kg of cattle dung with a shovel and put it into the machine manually… My back ached and I was exhausted every day.

Apparently, at times, the pipes carrying liquid fertilizer made from fermented cattle dung would come off and cover his head! However, it was impressive to hear him happily say, “I am living a stimulating life, taking on new challenges as I near retirement.”

The liquid fertilizer and compost produced at the experimental plant are spread by our own hands on the fields of farmers participating in the experiment. It is Daihatsu’s mission to provide safe products, and we are doing our utmost to express our gratitude to the people of Ryuo Town for accepting our products.

Akito Watanabe – Engaged in the Development of the Generator

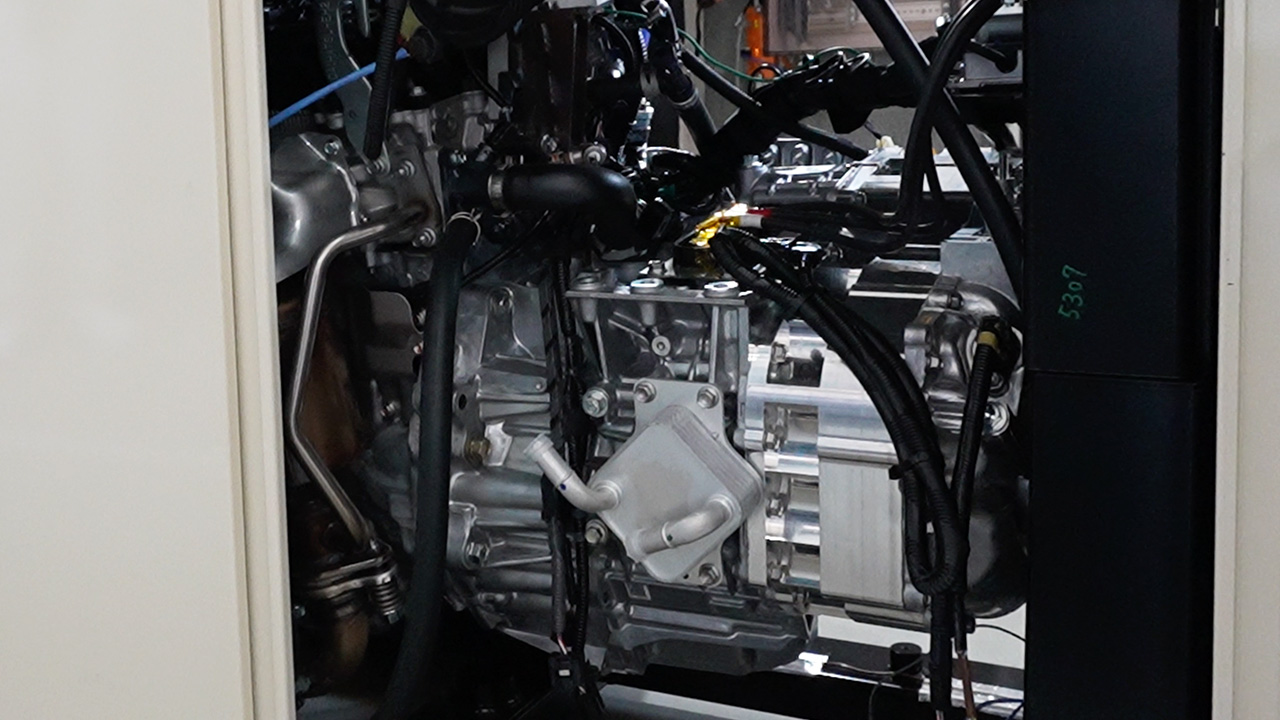

A generator converts biogas generated from cattle dung into electricity. The contents of the generator were filled with Daihatsu’s unique technologies and efforts.

The first generator prototype was made by disassembling a generator used at construction sites, taking out the engine, and replacing it with an engine from CNG Mira (an automobile that runs on natural gas), which Daihatsu used to sell. I felt moved the moment we were able to actually generate electricity!

If a gasoline engine is used as a generator, it must run 24 hours a day, 365 days a year. This means that an automobile would have to be durable enough to run for 800,000 km (compared to the usual 100,000 km)!

Since the fuel and usage are completely different from that of an automobile, it seems that various ingenuity was put into making them.

First, a small-scale durability test with methane gas was conducted at the Shiga Technical Center, and parts with less wear were selected.

↓

They were brought to the Kyushu Development Center, which can operate 24 hours a day, via ferry, etc.

↓

Durability testing was conducted with the cooperation of the Engine & Drivetrain Evaluation & Analysis Department.

↓

In cooperation with members of the Ikeda Development Test Building, every bolt was disassembled to measure the wear and then reassembled. (This was repeated three times during the 3,500 hours of durability testing!)

They were able to achieve so much through an overwhelming work process!

Engine part of the first generator prototype used in the experiment phase

Engine part of the first generator prototype used in the experiment phase

In this experiment, we used a motor designed for the generator, but eventually we would like to use the same motor used in the automobile and create Daihatsu’s unique product. The generator development team comprises people who have worked together for over 20 years and know each other well. With this team and the addition of new members, we at the lively BR Bio Project Department are moving on to the next stage.

Takashi Hara – In Charge of Overall Progress Management and Business Feasibility Studies

The Ryuo Biogas Project will only be a sustainable initiative if the cycle of crop farmers, livestock farmers, and the manufacturer is “well-oiled.”

It must be difficult to study the feasibility of the project while listening to the opinions of both the people of Ryuo Town and Daihatsu. Mr. Hara tells us his thoughts.

We are proceeding with this project, while thinking about how we can make everyone, including Ryuo Town, and the crop farmers, livestock farmers, and Daihatsu, happy. We will be glad if cattle of Omi Beef, which provide us with raw materials, and agriculture products grown with bio-liquid fertilizer and compost produced by fermentation are branded as “Made in Ryuo” and spread throughout Japan.

Mr. Hara used to be a member of the Aftersales Service Division, and he is always conscious of what he can do to make customers happy.

Since his job requires a lot of coordination not only within Daihatsu but with people outside the company, he sometimes refers to the members, including himself, as the “The Arrangers”!

When I talk to people involved in the project, I can feel how serious everyone is. Of course I am also serious about the work, but I must admit that I am lacking in some areas and rely on people around me in many aspects… I will do my best to learn more, expand my network, and grow!

Thoughts for the Future

I could sense the people I interviewed were not only happy about the completion of the experimental plant, but already look beyond that with passion. Step by step, everyone is making steady progress toward a future where this biogas plant will nurture a sustainable global environment. Seeing these “Partners” made me realize that I, too, am a member of the team that will build the future together.

Thank you for reading!

A Work at the Experimental Plant

Related links

The people in this article

-

The BR Bio Project Department

Yasushi Oba

-

The BR Bio Project Department

Nobuhiko Furuta

-

The BR Bio Project Department

Kenji Tani

-

The BR Bio Project Department

Akito Watanabe

-

The BR Bio Project Department

Takashi Hara

During this project, I always told other members, “To take on a new challenge, you must fail.” This is because you cannot determine where the limit is unless you fail once. True to my words, the project members have certainly failed (laughs). That is why we were able to hit the ground running with this biogas plant experiment. I am convinced that the know-how gained from our failures is what led us to this unprecedented initiative.