Daihatsu cars can be found outside Japan. In Indonesia, we have established a local Research & Development Center and manufacturing plants. Today, we take a close look at Karawang Assembly Plant 2, which was launched in December 2024.

This plant is different from those in Japan, though.

Takahashi-san, from the Inner Communication Group, visited Indonesia to gather information for this article.

Daihatsu and Indonesia

The relationship between Daihatsu and Indonesia started about 50 years ago in 1975. We initially launched production in Indonesia in collaboration with local companies.

This eventually led to the establishment of PT Astra Daihatsu Motor (ADM) as a joint venture in 1992. By leveraging Daihatsu’s technologies in Japan to continually produce vehicles ideally suited to the local market, we have grown to become Indonesia’s largest automaker in terms of production volume.

Daihatsu and Indonesia, partners for more than half a century

Introducing Karawang Assembly Plant 2

Let’s take a close look at Karawang Assembly Plant 2, our new plant in Indonesia.

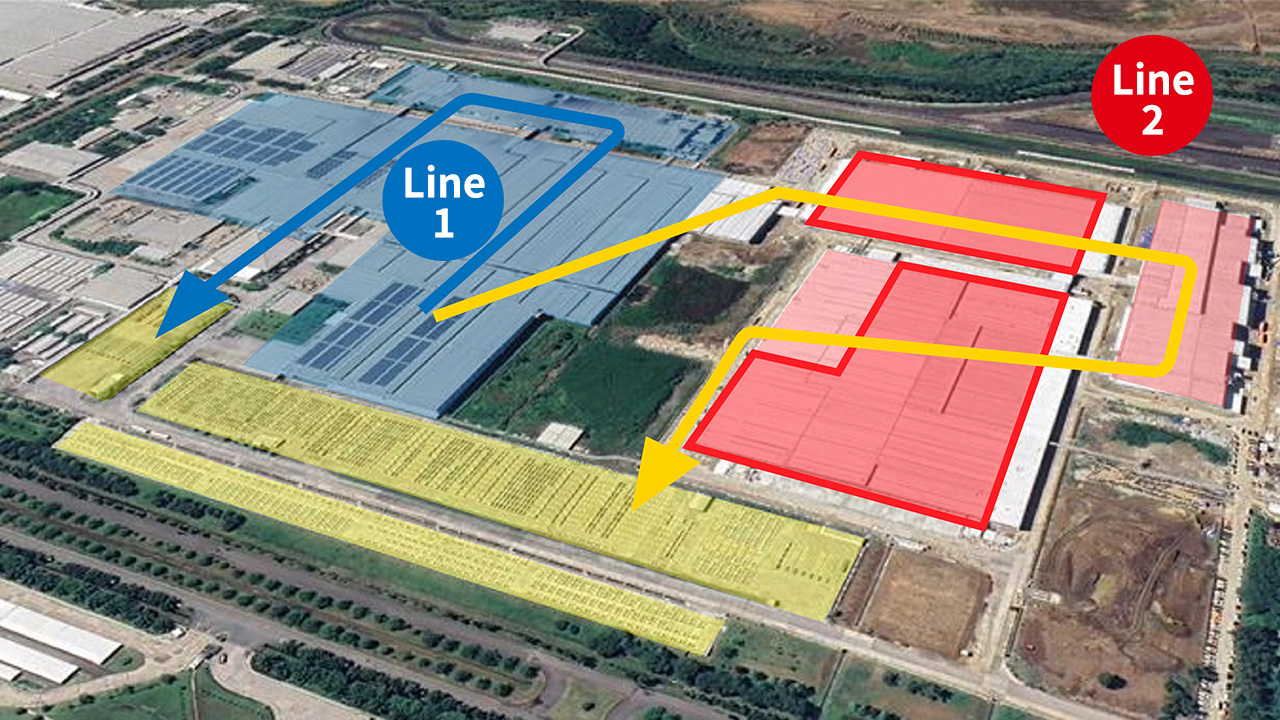

The Karawang Assembly Plant is located on a vast site about 50 km from Jakarta, the capital of Indonesia. Line 2 is situated right next to Line 1, which was launched in 2012.

Overall view of Karawang Assembly Plant

Overall view of Karawang Assembly Plant

Karawang Assembly Plant 2

Karawang Assembly Plant 2

This new plant incorporates plenty of the latest technologies for the environment and production efficiency. With the adoption of eco-friendly painting technologies, and greater use of welding robots to improve the automation ratio, the launch was led by our local staff.

The most significant feature of this plant is the wall-less layout of the assembly area.

What Is a Wall-Less Layout?

These are some photos of the actual plant.

As you can see, this plant has no external walls!

This type of construction has never been seen in automotive plants in Japan.

But why was it constructed this way?

The idea was originally put forward, as an environmental consideration, to create a plant that consumes less energy while ensuring efficient circulation of air within the building.

Utilizing Natural Breezes

Indonesia has a hot and humid climate all year round, so a lot of energy is required to create a cool environment within plants. However, we were able to take advantage of natural breezes to achieve a comfortable environment where energy consumption could be reduced.

Minimizing Logistics Distances

Another benefit of wall-less layout was that we were able to reduce transport distances, and increase the speed of parts delivery, for more efficient logistics within the plant.

Meeting Challenges Through Ingenuity

While it is a challenge to deal with dust coming in from outside, we maintain a clean plant through daily cleaning and regular monitoring. However, Indonesia is famous for its frequent severe squalls during the rainy season. To keep the wind and rain from entering the building, we applied our ingenuity to set back the equipment a long way from the building eaves, while creating a slope to the floor and incorporating drainage channels.

Although difficult to see in this photo, the plant was suddenly hit by strong winds and heavy rain during research for this article.

Greater Eco-Friendliness

Another idea that we adopted to reduce energy consumption was to install solar panels on the plant roof for power generation.

These initiatives will help to achieve carbon neutrality for ADM as a whole and for Indonesia as well.

Eliminating Barriers Within Organizations

This wall-less concept is not just limited to the plant though. In a similar way, different departments were able to overcome organizational barriers to successfully launch the plant.

We asked Tsuruta-san, on assignment from Japan, and Fanly-san, a local ADM member, for their thoughts.

Fanly-san, Production Engineering Assembly Dept.

I have a strong sense of working for ADM as a whole, rather than just working in a department. I’ve rotated through other jobs as well, so I understand the difficulties that other departments face. I think one of the strengths of ADM is that when faced with these difficulties, we can overcome them together.

(From left) Yatagai-san and Basri-san from KAP* Production Assembly 2 Dept.; Fanly-san, Tsuruta-san, and Nakamori-san from Production Engineering Assembly Dept.

(From left) Yatagai-san and Basri-san from KAP* Production Assembly 2 Dept.; Fanly-san, Tsuruta-san, and Nakamori-san from Production Engineering Assembly Dept.

*Karawang Assembly Plant

Other comments that we received included;

“We successfully launched this plant by working as One Team, comprising business partners, plant workers, and engineers,” and “I want ADM to not only be my workplace, but my second home as well.”

Such comments reinforced the image of ADM as a place where people can come together to work in a pleasant atmosphere.

The following people were also interviewed when preparing this article.

(From left) Inoue-san, Yasuda-san, and Paradhya-san, David-san and Ito-san

(From left) Inoue-san, Yasuda-san, and Paradhya-san, David-san and Ito-san

(From left) Roberto-san, Kintsuji-san and Yudi-san, Miyauchi-san and Irfan-san

(From left) Roberto-san, Kintsuji-san and Yudi-san, Miyauchi-san and Irfan-san

(From left) Fukui-san and Aditya-san, Sinaga-san and Dimas-san, Kuwata-san

(From left) Fukui-san and Aditya-san, Sinaga-san and Dimas-san, Kuwata-san

(From left) Obata-san, Krido-san, Ooba-san, Suryo-san and Fujishiro-san

(From left) Obata-san, Krido-san, Ooba-san, Suryo-san and Fujishiro-san

(From left) Bahrul-san, Adhan-san, Hirate-san

(From left) Bahrul-san, Adhan-san, Hirate-san

(From left) Hirakawa-san, Doni-san, Ueno-san, Nakamura-san

(From left) Hirakawa-san, Doni-san, Ueno-san, Nakamura-san

[Video] Introducing ADM, an Ever-Evolving Company

Going forward, Team ADM will continue providing customers in Indonesia and the rest of the world with high-quality, low-cost cars produced by ADM.

We finish this report with a video introducing ADM. We hope you enjoy it!

And finally, a big thank you to the people of ADM.

Terima kasih!

*Click the image to see a larger version.

*Click the image to see a larger version.

Tsuruta-san, Production Engineering Assembly Dept.

In Production Engineering Assy, we’re always talking with members of the manufacturing team. I think it’s an easy environment for communicating about work and other matters.