Reducing Waste at Plants and Other Facilities / Production, Logistics, and Other Initiatives

-

Fundamental Approach / Goals for 2025 / Flow of Materials

-

Vehicle Recycling Initiatives in the Product Design Stage

-

End-of-life Vehicle Recycling Initiatives

-

Reducing Waste at Plants and Other Facilities / Production, Logistics, and Other Initiatives

Reducing Waste at Plants and Other Facilities

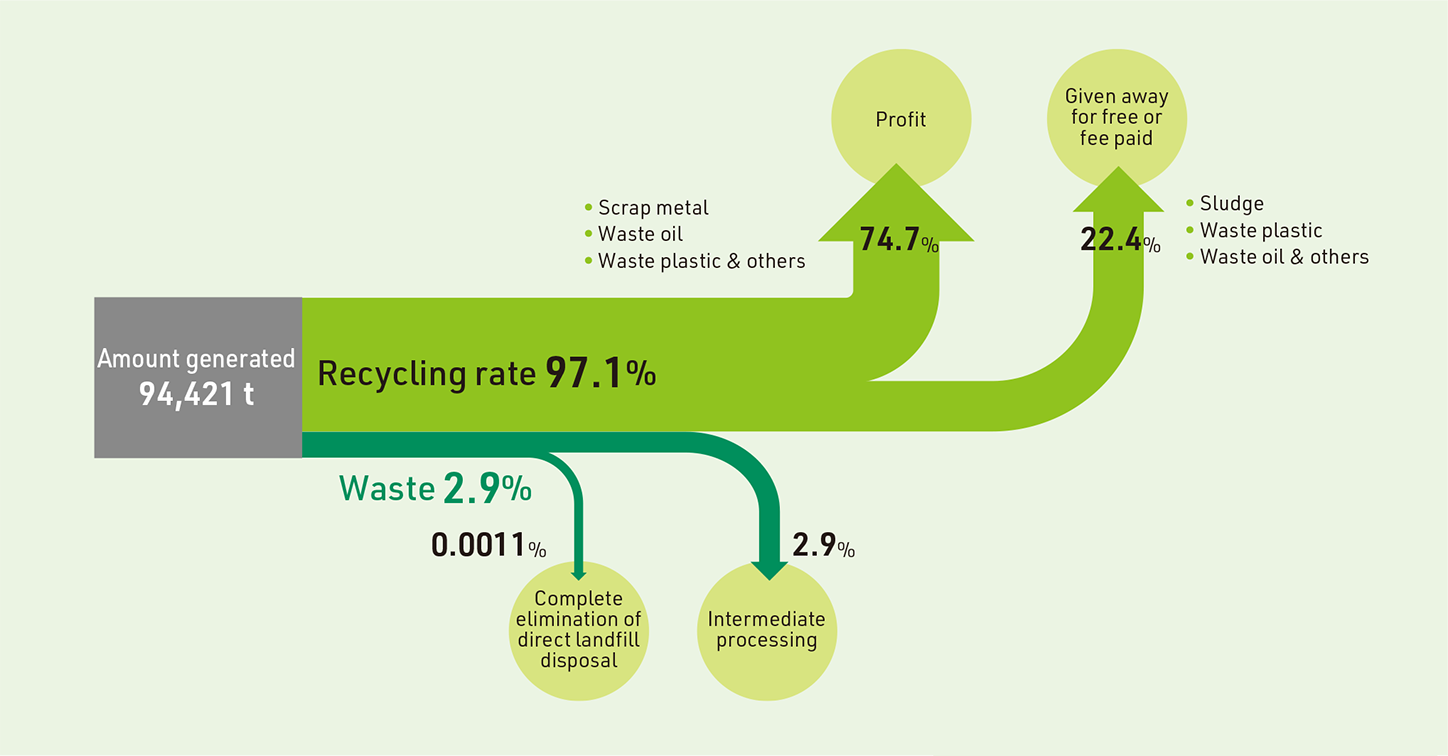

Daihatsu has made efforts to recycle scrap metal, waste plastic, and other waste materials generated during production, and as a result, now recycles 97.1% of waste material released from plants. In order to reuse such waste material as resources, however, recovery, transportation, and recycling require further energy usage. To address this issue, we have focused on “reduce” in order to decrease the amount of waste generated, promoting the effective use of resources. When punching out parts from steel plates using a press, for example, it is possible to curtail the generation of metal scrap and achieve efficient production using less material and less energy by adjusting the positioning of the molds and the sizes of the steel plates. By adopting such innovations, we will shift the focus of our initiatives for reducing waste to developing technology for manufacturing cars with less material.

Types of waste material and recycling methods1

| 2024 (calendar year) data | ||

| Category (Main Content) |

Percentage of Total Waste | Processing Method |

|---|---|---|

| Scrap metal | 74.45% | Payable for recycle, profit |

| Sludge | 12.90% | Payable for recycle, intermediate processing |

| Waste plastic | 4.64% | Payable for recycle, profit |

| Waste oil | 4.06% | Payable for recycle, profit |

| General materials | 1.54% | Payable for recycle, profit |

| Waste acids | 0.43% | Payable for recycle, profit |

| Waste alkalis | 1.40% | Payable for recycle |

| Others | 0.58% | ─ |

1. Scope: Daihatsu production sites and Daihatsu Motor Kyushu

Waste Material Processing Flows2

2024 (calendar year) data

Production, Logistics, and Other Initiatives

Fundamental Approach

The manufacture of automobiles entails the use of a variety of different resources, including metals such as iron and aluminum, resin, glass, and rubber. By focusing on details in processes including development, manufacture, and logistics, Daihatsu is pursuing the creation of small-size cars using minimal resources.

In addition to vehicle manufacturing that uses minimal resources, based on various automotive recycling laws and regulations in Japan and overseas, we aim from the design and development stages to develop cars that facilitate the implementation of the 3Rs to promote the proper processing of end-of-life vehicles. We will also encourage the expansion of car-to-car recycling in which we reuse resources recovered from end-of-life vehicles in the manufacture of new vehicles.

Examples of Initiatives

Paper Usage Reduction: Vehicle Instruction Manuals

Daihatsu is gradually reducing the size of our vehicle instruction manuals, thereby reducing the use of paper resources.

| ○: Started lightweight (FY) | ||||||||||

| Models | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | 2024 | 2025 | 2026 |

|---|---|---|---|---|---|---|---|---|---|---|

| Hijet Caddie | ○ | ○ | ○ | ○ | ○ | ○ | End of sales |

|||

| Mira e:S | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Mira Tocot | ○ | ○ | ○ | ○ | ○ | End of sales |

||||

| Tanto, Rocky | ○ | ○ | ○ | ○ | ○ | End of sales |

||||

| Taft, Gran Max | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||

| Hijet Atrai, Hijet Truck, Hijet Cargo |

○ | ○ | ○ | ○ | ○ | ○ | ||||

| Move Canbus | ○ | ○ | ○ | ○ | ||||||

| Move | ○ | |||||||||

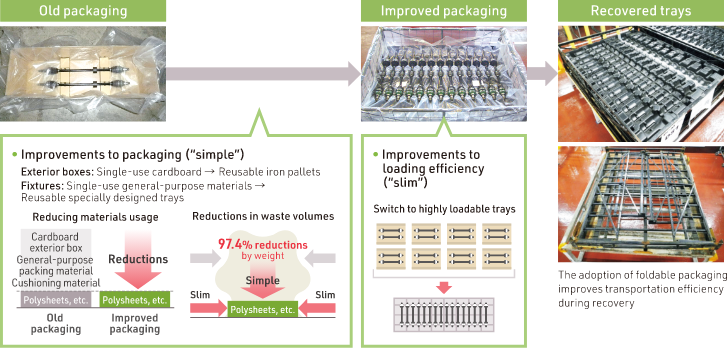

Reducing Waste by Improving Drive Shaft Packaging (Adopting Returnable Containers and Increasing Loading Efficiency)

Daihatsu developed special trays for transporting drive shafts that are highly loadable, reusable, and lightweight. As a result, we have succeeded in reducing the weight of our drive shaft packaging waste by 97.4%.