Indonesia business

7-seater MPV "XENIA"

7-seater MPV "XENIA"

ADM R&D Center opening ceremony (Indonesia) *

ADM R&D Center opening ceremony (Indonesia) *

* in 2017

Main Initiatives

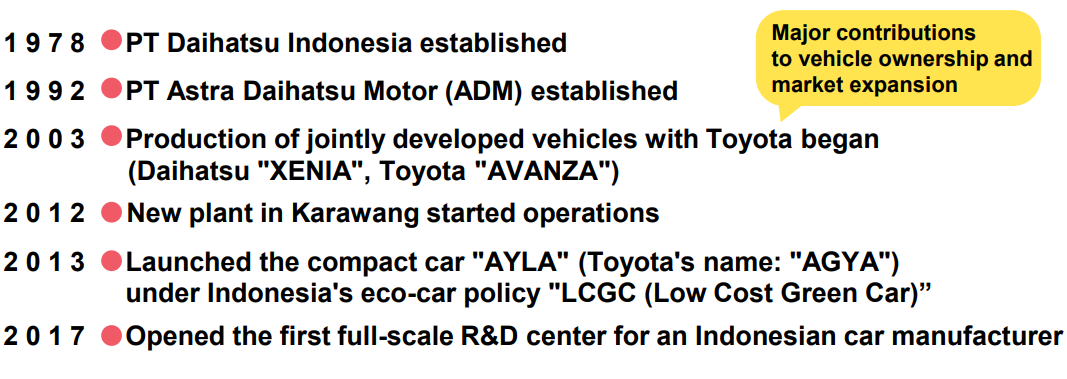

■Started joint development projects with Toyota in the 2000s

Daihatsu and Toyota began a joint development project in the 2000s to create a new genre of product in Indonesia by combining their respective vehicle development and production technologies. The new model was a 7-seater 3-row minivan with a hatchback, which is popular in Indonesia. It utilized Daihatsu's strengths in compact car manufacturing. It was released in 2004 as the Daihatsu “XENIA” and the Toyota “AVANZA.” Production was handled by PT Astra Daihatsu Motor (ADM). This new model pioneered a new genre of stylishly designed compact minivans. It became very popular for its high quality at an affordable price, and the number of units shipped from the start of production exceeded the initial plan, significantly contributing to popularizing cars and expanding the market in Indonesia.

Launch event for Daihatsu “XENIA” and Toyota “AVANZA”

Launch event for Daihatsu “XENIA” and Toyota “AVANZA”

The first generation "XENIA"

The first generation "XENIA"

■ Quick response to the “Low Cost Green Car (LCGC) ” eco-car policy

In the 2010s, Daihatsu was quick to respond to the “Low Cost Green Car (LCGC)” eco-car policy under consideration by the Indonesian government. It developed a new model that incorporated the technology and expertise for manufacturing small, lightweight, affordable cars that it had cultivated with the “Mira e:S” mini vehicle in Japan. Production of the Daihatsu “AYLA” and Toyota “AGYA” began at the new plant in Karawang, which started operations in 2012. The vehicles were launched on the market in 2013 ahead of other companies. Production of the Daihatsu “SIGRA” and Toyota “CALYA,” popular MPV models, began in 2016.

LCGC eco-car Policy Conformity Phase 1

LCGC eco-car Policy Conformity Phase 1

The first generation “AYLA”

LCGC eco-car Policy Conformity Phase 2

LCGC eco-car Policy Conformity Phase 2

Multipurpose passenger car “SIGRA”

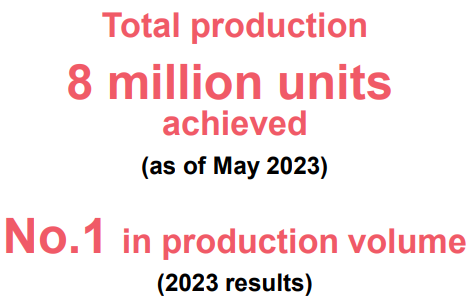

■Promotion of localization to develop the automotive industry and realize a sustainable society

ADM has the largest R&D center of any Indonesian car manufacturer. Many local engineers and designers are active there. It conducts tests in an environment unique to Indonesia, promoting the development of vehicles that are best suited to the local area and the cultivation of human resources. Local production is also expanding. Two plants have a combined production capacity of 530,000 units, making them the largest in Indonesia. The plants are based on the “Simple, Slim, Compact (SSC)” concept. They are designed to provide a safe and comfortable working environment while also achieving high productivity and quality. The plant in Karawang is currently preparing to launch its second production line. It is expected to become the latest plant to achieve carbon neutrality. In addition, Daihatsu is also promoting the local production of parts. The production of CVTs, which were previously exported from Japan, has been switched to Daihatsu Drive Train Manufacturing Indonesia (DDMI), which was established in 2021. Daihatsu will continue to promote localization to help develop the Indonesian automotive industry and realize a sustainable society.

PT Astra Daihatsu Motor (ADM) Karawang Plant

PT Astra Daihatsu Motor (ADM) Karawang Plant

PT Daihatsu Drivetrain Manufacturing Indonesia (DDMI)

PT Daihatsu Drivetrain Manufacturing Indonesia (DDMI)